Choosing the wrong construction procurement structure for a project is like isolating designers and builders so that neither can take into account the other team’s contributions. This can turn a profitable project into a money-losing endeavor. Yet, many companies default to familiar methods, instead of evaluating which procurement method will work best for each project. By understanding the types of construction procurement available, construction companies can bid smarter, maximize value, and avoid costly mismatches between project needs and procurement approaches.

What Is Procurement in Construction?

In construction, procurement is the process of acquiring the raw materials, components, finished goods, labor, and services needed for building projects. It covers every step from selecting subcontractors and suppliers to negotiating contracts and syncing deliveries, as well as all construction phases.

The procurement process typically begins during project planning and continues through project completion. Throughout the project lifecycle, procurement teams define project requirements, solicit bids from vendors, evaluate proposals, award contracts, and manage ongoing supplier relationships. Different procurement methods determine how each project’s responsibilities, risks, and controls are distributed among project owners, contractors, and other stakeholders.

Key Takeaways

- Construction procurement processes, beginning with supplier selection through delivery management, affect project costs, timelines, and quality.

- There are five main procurement methods—design-bid-build, design and build, construction management, management contracting, and public-private partnerships—each allocating risks and control in different ways.

- Choosing the right method depends on timeline, budget flexibility, market conditions, and owner involvement.

Construction Procurement Types Explained

Matching the procurement contract type to the needs of the project can make a real difference to project success and the construction firm’s bottom line. Each approach allocates different levels of financial risk, design control, and management responsibilities among the project’s various stakeholders. Employing the wrong procurement method can cut into contractors’ margins through cost overruns and leave project managers struggling to deliver projects that are beyond their capabilities—for example, if they’ve only managed design-bid-build types but are now tasked with a design-and-build that requires them to manage design resources for the first time.

Different procurement types may also determine how companies compete for projects and manage resources. According to KPMG’s “2023 Global Construction Survey” of 257 global engineering and construction firms, 83% of respondents chose improving material and equipment cost estimates as a top strategy for overcoming supply chain disruptions, cost escalations, and resource constraints. How this focus on cost estimation manifests in each firm is crucial to how the company will choose a procurement type, since each method has different levels of cost certainty and control, ranging from fixed-price contracts to flexible cost-plus arrangements. The chosen method directly influences how companies estimate and manage their material costs.

For example, traditional contracts favor contractors that offer competitive pricing and precise estimates, while design-and-build arrangements suit companies better able to navigate fluctuating costs through specialized expertise and integrated solutions, such as a companywide ERP system with a procurement module incorporated. Construction managers must understand how each method affects cost visibility and how it aligns with their organization’s strengths to position their companies for success and prioritize projects with compatible clients and subcontractors.

The 5 Types of Construction Procurement Methods

Construction projects are typically handled though one of five procurement methods. Spanning linear, traditional approaches to integrated, multiphase contracts with accelerated delivery expectations, these methods are based on who makes design decisions, who’s accountable when issues arise, and who coordinates project teams. By understanding each method, contractors can bid on the projects they’re best suited for and choose material management styles that match their resources and objectives:

-

Design-Bid-Build (Traditional Procurement)

Design-bid-build separates design and construction into distinct phases with separate contracts. The project owner first hires architects and engineers to create complete design documents, then contractors submit competitive bids based on these finished plans—with owners typically choosing the lowest qualified bid.

This method gives owners maximum control over design and provides contractors with clear guidelines and cost expectations—and perhaps even predetermined lists of materials to procure—before beginning construction, making it the standard choice for projects that prioritize price over speed. However, this sequential process often takes longer than more integrated approaches, and contractors have limited input on designs, which can lead to missed cost-saving or quality-improvement opportunities.

-

Design-and-Build (D&B)

Design-and-build combines design and construction services under a single contract, with one contractor responsible for both phases. The contractor manages architects and construction teams, simplifying communication and accelerating the project timeline by overlapping design, procurement, and build phases.

This integrated approach provides owners with a maximum price and single accountability point early in the process, limiting disputes between designers, procurement teams, and builders. D&B procurement methods are often utilized for private-sector projects where speed to market matters more than the lowest cost. But owners sacrifice some control by outsourcing more design elements.

-

Construction Management

Construction management involves hiring a professional construction manager to oversee the project on behalf of the owner. The manager arranges individual trade contracts between contractors and the owner for specified work, such as plumbing or pouring concrete. The construction manager acts as the owner’s representative on the project, planning, scheduling, procuring materials, and coordinating work without assuming financial liability for cost overruns.

This method allows owners to use their preferred contractors and maintain cost control while gaining professional management expertise and logistics support throughout construction. Construction management works well for complex projects, where owners need cost transparency, plus the ability to make midcourse changes. But it requires multiple contracts, which introduces new risks arising from having various contractors working on the same job.

-

Management Contracting

Management contracting places a single contractor in charge of the construction phase, who then manages subcontractors to perform the work. Management contractors assume the responsibility for all subcontractors and the work they do, shrinking financial risks for owners.

This approach saves time by permitting different teams to procure materials and work on segmented phases simultaneously, letting teams begin some material acquisition and construction before completing the overall design. But from a risk perspective, that is as scary as it sounds. It raises the risk of rework, for example, if subsequent designs affect completed work. Consequently, the management contracting approach requires careful planning, experienced management, and a clear understanding of the risks involved. It suits large, complex projects where early contractor involvement and expertise add value and help control costs and quality. However, due to its compartmentalized nature, the final project cost estimate often remains uncertain until the manager has awarded all contracts and combined all costs—which may not happen until after work has begun. And mistakes can drive the cost up further.

-

Public-Private Partnership (PPP)

Public-private partnerships bring together government entities and private companies, with the private sector usually responsible for financing, building, and often operating the resulting public infrastructure. The private partner typically handles some or all design, construction, financing, and long-term maintenance phases in exchange for ongoing government payments.

These relationships are often long term, potentially spanning decades. They make it possible for governments to use private sector expertise to create large-scale public projects without major up-front capital investment or significant financial risk. PPPs tend to be used for major infrastructure projects, such as hospitals, schools, or transportation systems. But the complex contracts and financing arrangements they require can hamstring flexibility.

Additional Procurement Types

Beyond the five primary methods, several hybrid and specialized procurement approaches are available to address unusual project needs. Many companies, especially those managing multiple construction projects at the same time, rely on a combination of these procurement strategies:

- Integrated project delivery (IPD): IPD brings owners, designers, and contractors together as equal partners, sharing risks and rewards through multiparty agreements that prioritize collaboration at all stages.

- Two-stage tendering: This multiphased approach allows owners to select a contractor based on qualifications determined during the initial design stage, then negotiate construction prices for further work once designs are fully developed and material needs are clearer.

- Cost-plus contracts: Under cost-plus contracts, owners pay actual construction expenses plus an additional fee to shift cost risk to the owner and provide complete transparency for all project costs, including procurement.

- Target cost contracts: During the estimate phase, the contractor calculates a “target cost” for the project. If the final material and labor costs are under or over target, the contractor and project owner split the savings or expenses, respectively, based on predetermined percentages.

- Framework agreements: These agreements establish long-term relationships with prequalified contractors to cover multiple projects, reducing procurement time and building working relationships.

Considerations for Choosing a Procurement Type

The right procurement method should align project costs, timelines, construction management style, accountability, and desired outcomes. Therefore, the final choice must suit both the contractors’ abilities and the owners’ plans and expectations. When choosing the ideal method, both parties should consider these criteria:

- Timeline: Fast-track projects typically benefit from concurrent design and construction phases, such as those found in the D&B or management contracting methods. Conversely, when the owner’s vision outweighs scheduling concerns, a traditional design-bid-build approach may be more appropriate. Shorter timelines also affect material availability and pricing, as rushed projects can result in paying premiums for expedited deliveries.

- Size and complexity of project: Large projects with multiple trades and systems often require more structured management approaches, such as construction management or management contracting, to coordinate procurement and inventory management across several construction phases. Smaller, straightforward projects often can succeed following traditional procurement methods.

- Budget flexibility: Fixed-price contracts—like those used with the design-bid-build method—provide certainty but squelch mid-project flexibility. More flexible models, such as cost-plus or target cost arrangements, allow for changes but come with additional financial risk for owners or contractors—or both, depending on the project. Strict budget constraints generally work best with procurement methods that lock in material costs early, which helps to minimize uncertainty and any likelihood of a mid-work cash crunch.

- Contractor availability: In a tight local market, certain procurement methods may do a better job than others at attracting the most qualified bidders. This is especially true for highly specialized or complex jobs, for which the number of available contractors may be limited to begin with. For example, methods that bring in contractors early, such as D&B or construction management, let project owners fill key roles before the supply of qualified contractors dries up. Procurement methods that offer guaranteed payment terms, such as cost-plus or target cost contracts, can stand out and attract top talent by lowering their risk.

- Client involvement: Owners wanting hands-on, ongoing input on the project should choose approaches where they maintain control, such as construction management or design-bid-build. Methods with more contractor control, such as D&B, may be more appropriate for projects where the owner trusts the contractor to deliver on their shared vision. This works especially well when owners lack the capacity or internal expertise to procure and store materials, manage contracts, or make timely decisions.

- Market conditions: Economic factors, labor and material availability, and market prices should factor into procurement decisions. For example, the price of steel sheets and strips rose 38% from February 2023 to February 2024, then fell 29% by February 2025, according to Federal Reserve data. Projects relying on similarly volatile materials often call for flexible procurement approaches, like management contracting, that can accommodate material substitutions, vendor changes, or longer lead times to capture price dips.

- Project risk: Owners that prioritize risk mitigation often choose methods that spread accountability. Traditional procurement, for example, transfers construction risk to contractors, while D&B holds contractors accountable for design issues. Choosing the right contract method for a specific project should involve weighing various risks for delays, cost overruns, and performance failures in order to pick partners well suited to navigating the most pressing challenges.

Your Procurement Strategy Needs the Right Procurement Software

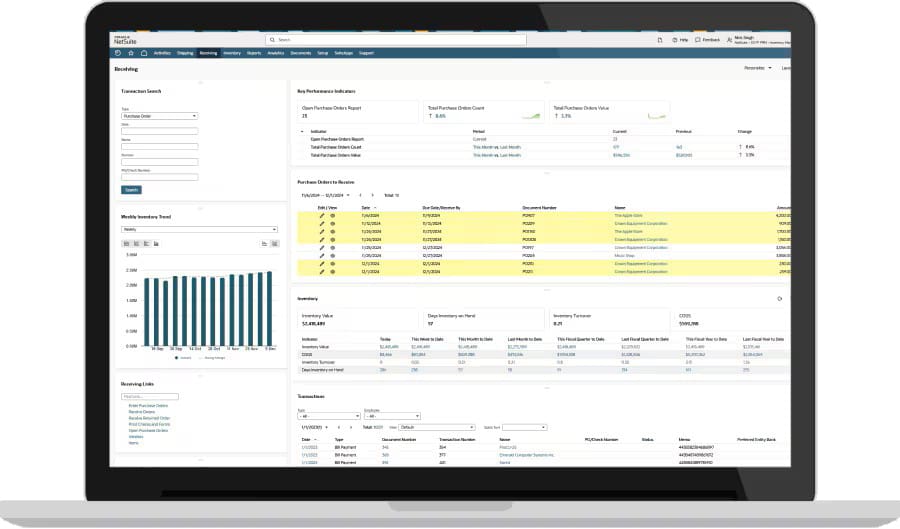

Managing different procurement methods for multiple projects creates administrative hurdles beyond the capabilities of spreadsheets and manual processes—and can lead to missed deadlines, budget overruns, and strained vendor relationships. NetSuite Procurement, part of the NetSuite Construction ERP cloud-based business software suite, monitors material costs, supplier performance, and contract compliance for all procurement types and provides construction companies with real-time insights into each project. It can automate purchases, track deliveries against project schedules, and consolidate spending data, producing the information business leaders need to improve budgeting and negotiate better rates with suppliers. Firms can configure the system’s flexible workflows to fit their chosen procurement method for each job. NetSuite integrates procurement data with management, inventory, and accounting systems, helping construction firms decrease material waste, avoid costly delays, and maintain records for regulatory compliance and internal accountability.

NetSuite’s Purchase Management Dashboard

Because construction procurement methods influence every step of construction projects from initial bidding through final delivery, recognizing which one is the right one can set up a project for success. Appropriate methods should balance cost control, risks, and management complexity against each project’s unique specifications and market conditions. As construction projects grow more complex and margins tighten, companies that choose a procurement approach that matches their capabilities with their clients’ expectations position themselves to win contracts and deliver successful projects on time and on budget.

Construction Procurement Types FAQs

What is material procurement in construction?

Material procurement in construction is the process of sourcing, purchasing, and delivering raw materials for projects. It involves identifying suppliers, negotiating contracts, managing orders, and coordinating deliveries, aligning each step with scheduled construction phases, quality standards, and budgets.

Are construction submittals part of procurement?

Submittals are one part of the procurement process. A submittal is a contractor’s formal presentation of product data, samples, and specifications that aims to verify that proposed materials and techniques meet contract requirements. Once the submittal is approved, the contractor can purchase materials and install them at the jobsite.

What does a construction procurement manager do?

Construction procurement managers own the project “buyout”—the process of turning the estimate into committed costs. They prequalify suppliers and subcontractors, run RFQs, negotiate terms, issue purchase orders and subcontracts, and time deliveries to the construction schedule. They sit between the field and vendors to protect the budget, meet specifications, and keep work moving.