As technology continues to advance and the demand for faster, safer and more efficient construction grows, the industry is facing increasing pressure to adopt automated solutions. To meet these challenges, businesses must carefully navigate complex technologies, such as robotics, artificial intelligence (AI), drones and 3D printers, while also considering the potential impact on their existing workforce and processes.

This article explores the world of construction automation and provides an overview of the benefits, types and future of these cutting-edge technologies, as well as some real-life examples and use cases to help businesses get started. By understanding automation’s potential and how to strategically implement it, decision-makers can effectively leverage these tools to improve their operations, better serve their customers and beat the competition.

What Is Construction Automation?

The primary goals of construction automation are to improve efficiency, safety and productivity for current workflows and to reduce labor costs and human error by methods such as implementing robotic equipment for tedious or repetitive tasks, surveying sites with internet-connected sensors and cameras and using 3D printers to quickly create customizable and complex components and structures that meet exact specifications.

Automation technology can significantly enrich a construction company’s operations and deliver projects faster and with higher quality and precision — but without proportionally increasing overhead or pressure on its workforce. Construction automation also enables businesses to expand their offerings by unlocking more complex project and labor capabilities. This is especially important in tight labor markets and/or during periods of skills shortages, where maximizing value from labor is a crucial element in staying competitive.

Key Takeaways

- Automating construction processes offers numerous benefits, such as increased efficiency, enhanced safety and faster project completion.

- Business leaders should strategically implement automation technologies that align with their specific needs and goals to maximize operational impact and return on investment (ROI).

- As automation continues to advance, construction companies must invest in the right tools, training and partnerships to maintain a competitive edge and build long-term success.

Construction Automation Explained

Construction automation encompasses a wide range of technologies that complete designated tasks, either independently, alongside human partners or as part of a larger system of human and autonomous elements. These technologies include tools such as self-operating machinery, robots, drones, 3D printers and AI algorithms. For example, robotic bricklayers can accurately lay thousands more bricks per day than the average human worker, while autonomous excavators can dig deep trenches for foundations with minimal human intervention. Beyond performing physical tasks, automation technology can help construction teams refine project management — for example, equipping drones with high-resolution cameras and sensors to quickly survey construction sites, gather data, flag unsafe conditions and monitor progress. (More on these use cases later.)

Automation in the construction industry continues to expand as more businesses implement these tools to improve overall efficiency, reduce costs, minimize waste and elevate safety standards on job sites. Additionally, many companies are automating their factories to build components and materials, delivering them to their final destinations only when sites are ready for them. As automation efforts continue to progress, savvy construction company leaders will be able to find new uses for this technology to continually innovate their workflows — but only if they invest in the infrastructure, human skills and expertise required to effectively leverage these new tools.

Why Should Your Business Invest in Construction Automation?

Investing in construction automation is a strategic move that helps companies complete more projects without sacrificing quality or increasing their labor, resource or time requirements. This is especially important in the modern construction industry, where costs are rising and the labor market is tight. According to the 2023 Workforce Survey by the Associated General Contractors of America, half of the respondents cited increasing costs as a driver of delayed, canceled or scaled back projects, while 61% cited labor shortages. Additionally, automating frustrating and tedious tasks in order to use staff skills and expertise more appropriately can help businesses prevent burnout and keep workers satisfied, productive and engaged. Beyond these immediate benefits, businesses that invest early in automation technology and staff training will be better positioned to adapt to future changes and growth opportunities in the market as the construction industry continues to evolve.

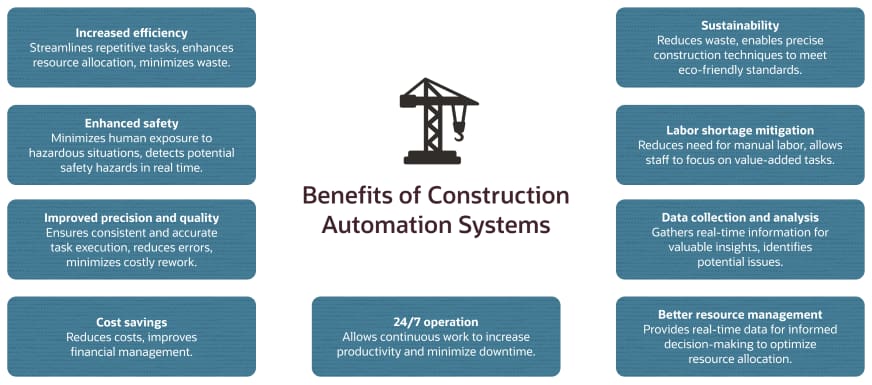

Benefits of Construction Automation

Construction automation offers a wide range of benefits that can help businesses deliver high-quality projects faster and more efficiently than ever before. Companies should also remember the indirect benefits, such as worker safety and sustainability, when choosing when and how to implement automation into their operations. Here are nine primary benefits to expect when automating construction processes.

- Increased efficiency: Automation can handle tasks quicker and more efficiently than humans, reducing the time required to complete projects. This includes repetitive tasks, such as bricklaying or prefabricating wall panels, as well as more complex tasks, such as 3D-printing components to create a supply inventory. Automated equipment and robots can work for hours on end, allowing construction firms to accelerate their timelines and take on more projects simultaneously without necessarily expanding their workforce. Additionally, managers can use data collected by automated systems to inform decisions about resource allocation and ways to minimize waste.

- Enhanced safety: Construction automation improves job-site safety by minimizing human exposure to hazardous situations, such as working at heights or in confined spaces, thereby reducing the risk of accidents and injuries to workers, as well as mishaps that can pause construction. For example, fully automated machines can complete tasks remotely, and semiautomated equipment like robotic limbs and exoskeletons can enhance and protect workers in the field. Moreover, drone cameras, advanced sensors and monitoring systems can detect potential safety hazards in real time, enabling swift corrective actions and preventing potentially dangerous situations.

- Improved precision and quality: When properly programmed and calibrated, automated systems and robots can perform tasks with unparalleled precision and consistency. By leveraging advanced technologies, such as computer-controlled equipment and sensitive sensors, construction firms can minimize discrepancies and deliver projects that meet or exceed client expectations. This improved precision and quality not only enhances customer satisfaction but also helps alleviate costly rework and delays. Additionally, this precision allows construction companies to calculate their costs more accurately and, in turn, provide customers with more reliable estimates and payment options.

- Cost savings: Construction automation can lead to significant cost savings per project by reducing total labor hours, minimizing wasted materials and expanding active work hours. Many of these cost-saving measures stem from other benefits in this list, including better resource management, improved precision and higher quality. When planning investments, accounting teams should also consider automation’s other, more indirect cost-saving measures, such as reduced costs for broken or wasted material disposal and avoidance of costly shutdowns and project delays because of injuries or accidents. Additionally, automation often generates long-term savings due to reduced maintenance and repair expenses, thanks to the increased precision and quality of these sophisticated systems. These cost savings can be retained for reinvestment, allowing for further growth and innovation.

- 24/7 operation: Unlike human workers, automated systems and robots can operate continuously, without breaks or downtime. This level of round-the-clock operation allows construction firms to complete projects faster and meet tight deadlines. Automated equipment can work through the night, on weekends and during adverse weather conditions, increasing the likelihood that projects will meet expected deadlines, even in the face of unexpected adversity. And while it’s important to regularly assess, repair and recalibrate machines, they’ll likely outlast human workers who often get tired, which can negatively impact their productivity. This increased output can help businesses take on more projects at once, thereby growing revenue.

- Better resource management: Many automated systems provide real-time insights into project progress, financial metrics, material usage and equipment performance, which allows construction managers to make data-driven decisions and on-the-fly adjustments when allocating materials, machinery and human workers. This level of visibility and control helps curtail downtime, optimize stock levels and ensure that resources are used efficiently throughout the entire project life cycle.

- Data collection and analysis: Automation in construction facilitates the collection and analysis of vast amounts of data, and it does so more quickly and accurately than a team of human analysts can. Sensors, drones, Internet of Things (IoT) devices and other automated systems collect real-time information about site conditions and completed work. This data can then be fed into advanced analytics tools and AI algorithms to identify patterns, predict potential issues and offer actionable suggestions to improve performance. Similarly, construction companies can use these tools to enhance their financial management and accounting practices to improve cash flow and investment returns. By leveraging this information, business leaders can mitigate risks and continually find areas where they can improve operations.

- Labor shortage mitigation: The construction industry often faces challenges related to labor shortages, with 52% of executives surveyed for Deloitte’s 2022 Engineering and Construction Industry Outlook report saying they face a “severe labor and talent shortage on the job site.” Automation helps businesses address this issue by reducing the need for manual labor for certain tasks and easing the burden on an overtaxed or understaffed workforce. Automated equipment and robots can take over mundane and physically demanding jobs, allowing human workers to focus on more complex and value-added activities, such as working with clients on new designs or innovating workflows. This shift in labor allocation can help construction firms maintain or enhance productivity levels, even during times of labor shortages.

- Sustainability: Construction companies are under growing pressure to follow sustainable practices, either to meet specific client demands or to adhere to government-mandated environmental regulations. These practices include enforcing responsible sourcing strategies and limits on material waste and emissions, as well as minimizing the environmental disruption to the area around the construction site. Automated systems can help meet these requirements by optimizing material cutting to reduce scrap and by following precise construction techniques to build structures with improved energy efficiency and smaller carbon footprints. By embracing automation, construction firms can demonstrate their sustainability commitments to customers and meet the growing demand for eco-friendly building practices.

Types of Construction Automation

Construction automation encompasses a wide range of technologies and solutions that cater to different aspects of the construction process. Therefore, businesses should strive to understand which applications will bring the most suitable benefits, especially if they’re operating on a limited budget for both the initial investment and ongoing staff training and support. From on-site equipment to off-site prefabrication, construction companies should choose the automation tools that will most improve their operations and will strengthen the quality — or expand the scope of — the construction projects that they specialize in. Here are 11 key types of construction automation.

-

On-Site Construction Automation

On-site construction automation involves using automated equipment, robots and drones at the actual construction site to complete tasks or assist human workers. Examples include fully automated concrete mixers, robotic welding assistants and site-monitoring sensors. By automating on-site processes, construction companies can reduce labor costs, improve safety and increase productivity.

-

Autonomous and Semiautonomous Construction Equipment

Autonomous and semiautonomous construction equipment includes vehicles and machines that can continuously operate with minimal or no human intervention, such as self-driving compactors, automated cranes and robotic demolition equipment. These systems use sensors, GPS and AI to effectively navigate the construction site, perform their assigned tasks and make real-time adjustments to their processes, which reduces the need for on-site human operators.

-

Robotic Automation

Construction robots use sophisticated programming to perform specific, preplanned tasks, such as bricklaying, drywall installation or painting. These robots are designed to work alongside human workers, increasing productivity and precision while reducing the risk of errors and accidents. Robotic automation can be particularly useful for repetitive or hazardous tasks because it allows human workers to focus on other, more mentally demanding work. For example, humans can design and place pipes for a new building, leaving the more dangerous welding to robots.

-

3D Printing

3D printing is an innovative construction automation technology that creates complex structures directly from digital models. The most common industrial application of 3D printing is known as additive manufacturing, where objects are built, typically at scale, by layering materials, such as concrete or plastic. This “printing” builds customizable components from the ground up, significantly reducing waste and streamlining the assembly process. In construction, 3D printing is often used to create architectural models and customized or less common building components, but some companies use it in the construction of larger buildings as well.

-

Drones

Construction companies are increasingly using drones to monitor inventory, progress and safety at construction sites. Drones are frequently equipped with high-resolution cameras and sensors to quickly and efficiently capture visual data. Many drones, or the systems they’re connected to, can then analyze that data and provide project managers and stakeholders with valuable insights into a project’s successes and areas that can be improved. These automated site inspections help businesses save time, reduce costs, improve safety and keep more up-to-date records on projects. This, in turn, gives both managers and customers increased transparency on progress and timelines. Additionally, companies can use drones for material tracking, thermal imaging and even delivering small tools and supplies to hard-to-reach areas of a job site.

-

Prefabrication and Modular Construction

Rather than automate the job site itself, many construction companies implement prefabrication and modular construction processes to manufacture building components or entire structures off-site. Then these materials are transported to the construction site for final assembly. Much like on-site automation, this approach uses automation technology to enable greater precision, reduce waste and speed up construction times, as compared to traditional methods, but it does so in a more controlled factory environment. This minimizes the impact of weather disruptions, equipment malfunctions, shortages and inconsistent quality control. Prefabricated and modular items range from simple components, such as wall panels and roof trusses, to full rooms or even entire buildings, depending on project requirements.

-

Building Information Modeling (BIM)

Building information modeling (BIM) is a digital representation of a construction project that serves as a comprehensive, three-dimensional version of traditional architectural designs and blueprints. These detailed and computer-generated designs include all relevant construction data, including materials, dimensions and design-specific characteristics. As designers modify them, BIM designs automatically apply any changes throughout the entire model, helping companies quickly identify and address potential issues during the planning stage. BIM also helps reduce risks and align objectives through construction sequence simulations that enhance collaboration among architects, engineers, contractors and stakeholders before and after building has begun.

-

Artificial Intelligence and Machine Learning

AI and machine learning algorithms analyze vast amounts of data from sensors, drones, IoT devices, smart equipment and other sources to identify patterns, optimize scheduling for maintenance and repairs, predict potential issues and recommend corrective actions. For example, managers can use AI to monitor equipment performance, learn specific maintenance steps and schedule uptime and downtime to help optimize energy consumption during the project. Some companies also leverage this technology to improve safety on construction sites by analyzing worker behavior to proactively identify potential hazards. However, it’s important to note that this technology, especially new applications of it, isn’t perfect and should still be checked and monitored by human construction experts in the field.

-

Automated Monitoring Systems

Automated systems can monitor various aspects of the construction process in real time, such as structural integrity, environmental conditions and worker activity. These systems continuously monitor the job site, using sensitive equipment to detect potential issues — such as changes in equipment before major malfunctions or hard-to-notice safety hazards — faster than humans can. Once identified, the system alerts project managers and other relevant staff to take corrective action. In addition to safety, automated monitoring systems can help improve overall project performance by providing valuable insights into construction operations and workflows.

-

Self-Healing Concrete

Self-healing concrete is an innovative construction material that can automatically repair cracks and other damage, extending the lifespan of structures and decreasing maintenance costs. The technology relies on special polymers or other components that are blended into the concrete mix to increase elasticity, flexibility and stress resistance, as well as bond over cracks to reseal them. This automated repair process can significantly improve the durability and resilience of buildings, bridges and other infrastructure, while also minimizing repair and labor costs. But as with all new construction technology, businesses should continue to watch for any impact on structural integrity to maintain high safety standards.

-

Virtual and Augmented Reality (VR/AR)

Construction companies can incorporate virtual reality (VR) technology into their project design and planning phases to allow architects, engineers and other stakeholders to immerse themselves in a digital representation of the project. This VR experience allows them to explore and interact with the design in a 3D environment to identify potential issues, inform layout decisions and create a more innovative and engaging collaborative space among team members. Augmented reality (AR), meanwhile, overlays digital information onto the real world to provide workers with real-time AR guidance for such tasks as assembly, installation and maintenance.

Examples of Construction Automation

Construction companies across the globe are embracing automation to enhance their work. From robotic bricklayers to 3D-printed structures, these real-world examples help demonstrate the potential of construction automation.

- Construction Robotics manufactures semiautomatic lifting robots, known as MULEs (material unit lift enhancers). As of October 2024, there were two available types of MULEs — the ML150 and the MZ100 — that follow guidelines set by human workers. While both robots specialize in lifting heavy construction materials, they’re specialized for different types of work. The ML150 attaches to materials to reduce their weight burden, allowing workers to easily move and place heavy materials weighing up to 150 pounds. The MZ100, meanwhile, is smaller and battery-powered to create a more mobile and versatile robot for on-site tasks, including bricklaying. With these robots, construction workers can carefully and repeatedly place large and heavy materials as if they were doing it by hand, but without the physical stress and delays that come with repeatedly moving bricks and other large materials.

- COBOD is a leading 3D-printing construction company whose printers automatically generate and apply major construction components, including concrete and mortar. These printers adapt to the specifics of each project, even for uneven ground or multibuilding projects, with minimal intervention from a small team of three to four human operators. COBOD’s printers also increase job safety, with built-in safety sensors, multiple emergency stops, shielded trusses and safety fences when operating at high speeds. COBOD is currently partnering with other construction companies to 3D-print buildings around the globe and expand the ways construction companies can leverage this new technology.

Construction Automation Use Cases

Because of the versatility and diversity of automated construction tools, business leaders need to focus on specific, deliberate ways to implement this technology or risk ending up with expensive gadgets that they aren’t using to their full potential. This, in turn, could impair ROI and hurt the bottom line. Here are seven specific use cases to consider for construction automation and some of the direct and indirect benefits they offer.

-

Bricklaying Robots

Bricklaying robots can lay bricks much faster than the average human mason. While robots are only just starting to reach the all-time manual bricklaying record (914 bricks in one hour, set by Robert Boll Jr. in 1987), these robots can maintain their above-average pace of 300 to 500 bricks per hour for long periods — even when laying significantly larger, heavier bricks — than a typical human mason. To do this, these machines use a combination of computer vision, laser scanning and robotic arms to precisely place bricks according to digital blueprints. Fun fact: Some of these robots can build the brick framework for an entire building in a matter of days.

-

Concrete 3D Printing

Concrete 3D printing involves using large-scale 3D printers to build concrete structures that follow the exact specifications set by digital models. This technology can significantly reduce construction time, labor costs, material waste and errors compared with traditional concrete pouring methods. For instance, a construction firm tasked with building a unique, curved concrete facade for a high-end office building could use concrete 3D printing to create the intricate design by “printing” the facade in sections off-site and then assembling them on location. This multistep approach helps the company achieve the desired aesthetic while minimizing on-site disruptions and ensuring precise, consistent results from specialized and carefully calibrated equipment.

-

Drones for Site Inspection

Drones equipped with high-resolution cameras and sensors can automate data collection throughout the job site, including on elevated floors and other out of the way areas. In this way, managers and compliance teams can monitor construction progress and flag safety hazards and other potential issues remotely to quickly gain a full view of the job from one central location. A construction manager overseeing a large-scale infrastructure project, for example, can deploy drones to regularly survey the site, capturing aerial images and video footage of the building’s framework. Then teams can zoom in on these high-quality images to look for any errors or anomalies and address them before they get buried by next steps, ultimately saving time and expense and improving overall project safety and quality.

-

Autonomous Excavators

Autonomous excavators use sophisticated sensors and algorithms to accurately dig trenches, grade surfaces and move materials according to predetermined plans. For instance, a construction team working on a large-scale land development project could deploy a fleet of autonomous excavators to handle the initial site preparation. By programming the excavators with the necessary site data and parameters, the machines can work around the clock to prepare the required gradient quickly and precisely, significantly accelerating the construction timetable and reducing the need for initial manual labor. This way, when workers arrive in the morning, they can start right away on more skilled work that requires human insight and expertise, such as planning the initial framework build.

-

Prefabrication and Modular Construction

Construction companies that use prefabrication and modular construction processes build components and structures in controlled factories before shipping them to construction sites for final assembly and placement, reducing on-site labor and construction time. A developer constructing a multistory apartment complex, for instance, may prefabricate bathrooms off-site. These bathroom sets include all necessary plumbing, electrical fixtures and finishes and are manufactured in an automated factory, ensuring consistent quality from one apartment to the next. Once complete, the structures can be transported to the construction site in bulk and easily installed in each apartment unit, thereby streamlining the construction process and speeding up completion rates.

-

AI for Project Management

AI allows construction workers and leaders to analyze large datasets from various sources, including the equipment discussed in the prior use cases, to provide valuable insights and inform decisions. For example, an AI-powered project management system can continuously monitor the construction site through drones and internet-connected equipment to monitor safety protocols and inventory levels. Then, managers can feed this data into AI algorithms to identify any discrepancies between the initial plans and the real-world construction, even if those discrepancies are too subtle to notice with the human eye. AI can also detect potential safety risks, such as unstable structures or workers not wearing proper protective equipment. This thorough view of the job site helps construction companies proactively address concerns and minimize delays to ensure that projects are completed on time, within budget and in accordance with the highest safety standards.

-

Self-Healing Materials

Self-healing materials can autonomously repair minor damages, such as cracks and fissures, without human intervention. The materials are typically concrete or asphalt and contain additives that act as healing agents when damage occurs, improving durability and extending the life of structures. For instance, in a bridge construction project, workers can embed concrete with special, bacteria-filled microcapsules that form calcium carbonate crystals capable of repairing small cracks. According to a 2023 study conducted by Vilnius Gediminas Technical University, which tested three different self-healing bacterium types, these materials could heal cracks up to 1 mm in width within 14 days. However, the study also found that bacterial viability and survival were significantly affected by the method of concrete preparation, temperature, pressure and other factors, so it’s important to regularly monitor structural integrity and check for any damage, as results can be difficult to predict with certainty.

Future of Construction Automation

As technology continues to advance, the future of construction automation will likely include more sophisticated robotics, more advanced materials and improved sensor technologies that will further streamline construction processes and increase overall efficiency. Additionally, the integration of construction automation with other emerging technologies, such as more powerful data transfer networks and the blockchain, may enhance connections among job sites and larger, more complex supply chains. This interconnectivity can help companies further customize their projects and offer specialized structures that follow more stringent requirements without compromising efficiency or speed.

These advancements will not only lead to new best practices when building structures but also help make them more sustainable, resilient and cost-effective. However, these new technologies will also bring new challenges, including dealing with modern data privacy and cybersecurity threats, and businesses must be prepared to invest and adapt to maintain the trust of their customers.

AI and Construction Automation

AI is a rapidly growing industry with new applications popping up around every corner, and construction is among the beneficiaries. As AI algorithms become more accessible and capable of processing larger volumes of data, they will further expand informed decision-making, workflow improvements and project outcomes. For example, AI-powered systems will be able to analyze data from across a construction site, encompassing worker devices, construction equipment and site surveyors to more accurately predict potential problems. Additionally, AI will likely be used to enhance the capabilities of construction robots, enabling them to perform more complex tasks, adapt to changing site conditions and collaborate with human workers. As AI continues to evolve, construction companies would be wise to monitor new development and uses to make sure their business is adopting modern best practices and staying ahead of their competition, which is often achieved through ongoing training, bringing in external consultants or hiring AI experts.

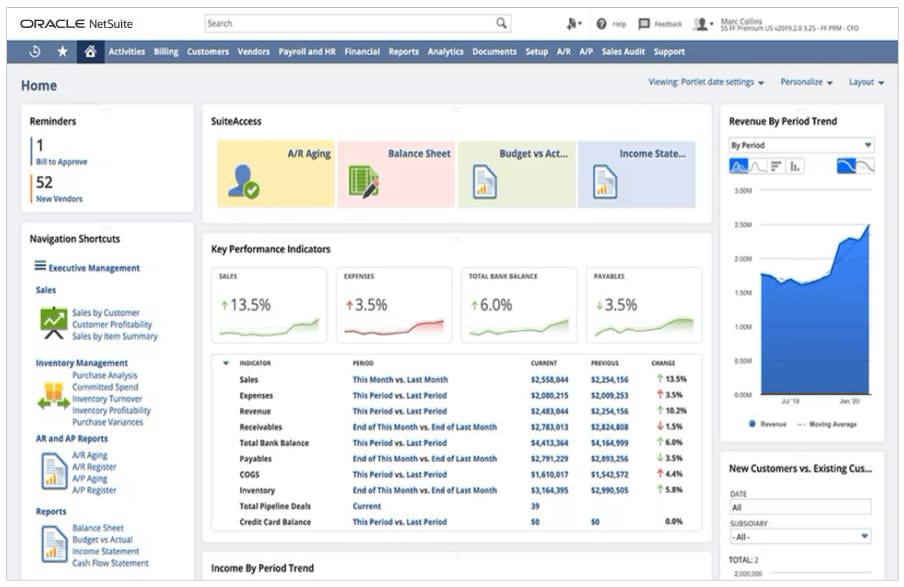

Improve Your Construction Management With NetSuite

As more construction companies embrace automation, they need a comprehensive strategy to stay competitive. With NetSuite’s cloud-based Enterprise Resource Planning (ERP) solution, construction companies can integrate and manage automation tools within a single, centralized platform, unlocking detailed, real-time monitoring of project progress, inventory, resource utilization and equipment performance. NetSuite’s built-in suite of digital tools is designed to help businesses streamline operations, improve collaboration and make data-driven decisions, giving construction managers more transparency into which processes are working and which may need adjustment.

NetSuite’s ERP system also provides powerful financial management capabilities, ensuring complete visibility into financial performance. By automating key financial processes and providing real-time insights into both overall and project-specific profitability, NetSuite empowers construction companies to make informed decisions that increase ROI and improve their bottom line. Additionally, NetSuite’s cloud-based system enables authorized users to securely access critical data and applications wherever and whenever they need to, improving collaboration among team members. And NetSuite is scalable and flexible, so construction companies can confidently implement new automation technology as they grow, building and maintaining long-term success.

For many construction companies, adopting automation technologies, including robotics and AI, is no longer a question of if, but when. As these technologies continue to evolve, businesses that find innovative ways to implement automation will be well positioned to improve the quality, speed and affordability of future projects. By staying ahead of the curve and investing in the right tools, staff training and techniques, construction companies can enhance their efficiency, sustainability, productivity and profitability, ultimately setting themselves up for long-term success in this highly competitive and demanding industry.

Construction Automation FAQs

How will construction be automated?

Future applications of construction automation will depend on each business’s specific needs and goals. Generally, businesses implement a variety of tools, such as robotic equipment, autonomous vehicles, drones, 3D printing and artificial intelligence algorithms, to complete repetitive tasks with great accuracy. As these technologies become more sophisticated, the tools will be able to handle more tasks with less human intervention, expanding the scope of their capabilities and freeing up staff for more complex tasks, such as developing new designs and directly working with customers.

What is an example of automation in civil engineering?

An example of automation in civil engineering is the use of autonomous excavators and bulldozers for moving earth and setting gradients for new projects. These machines can operate with minimal human intervention, using GPS and other sensors to follow digital plans and achieve the desired site layout to exact specifications, reducing the time and labor required for these tasks. These machines can operate 24/7 to complete these types of tasks overnight, saving customary workday hours for hands-on tasks that require a full construction crew.

How can AI be used in construction?

Artificial intelligence (AI) can be used in construction to optimize project planning, resource allocation and risk management. AI can help managers and project planners analyze vast amounts of data from past projects to predict potential issues, suggest optimal solutions and streamline decision-making processes. This technology can also be used to create digital models of potential plans to run simulations and stress test ideas before putting them into practice, ultimately improving project outcomes and reducing delays and costly rework.