A growing number of companies are turning to AI to help tame recurring disruptions in their supply chains and operate them more efficiently. Supply chain professionals are leaning on AI to identify patterns and anomalies in large data sets so they can predict trends, identify problems, and accelerate tasks.

Shifting trade policy and tariffs provide a timely example. Because AI-fueled supply chain management software can analyze companies’ global networks of vendors, factories, and distribution centers, the technology can quickly evaluate and suggest alternative arrangements when tariffs and trade rules change. Based on AI-generated recommendations, a company can decide to source from an alternate supplier, shift production to a different country, or reroute shipments through a US-designated foreign-trade zone to defer, reduce, or eliminate customs duties.

What Is AI in Supply Chain Management?

AI in supply chain management refers to using core technological capabilities—such as machine learning (ML), predictive analytics, computer vision, generative AI (GenAI), and AI agents—to plan and run networks for sourcing, producing, and distributing products and services.

Technology vendors are embedding AI into software for supply chain management, inventory management, and other operational essentials. These systems can help lighten supply chain-related workloads across various roles:

- Inventory managers can manage by exception when alerted to potential stockouts, instead of running their own day-to-day routines.

- Logistics managers can proactively reroute shipping when AI flags potential delays, in lieu of putting out fires after the fact.

- Warehouse managers can replace manual inventory counts with AI vision system scans to achieve faster, more accurate tallies.

- Procurement specialists can quickly draft sourcing requests, supplier performance reports, and other administrative documents, so they can focus on higher-value work.

Key Takeaways

- AI is being used to create more resilient and efficient supply chains that can better anticipate disruptions, automate tasks, and lower operating costs.

- The adoption of AI helps shift the focus of supply chain managers from manual, transactional work to more strategic, exception-based management.

- Successfully implementing AI requires a strategy to address data readiness, project complexity, and user adoption.

AI in Supply Chain Management Explained

AI adoption has accelerated along with increased use of cloud ERP systems that can gather data AI can use for supply chain analysis. In addition, new AI agents can plan and execute many complex supply chain tasks when given only a high-level directives.

More than one in four supply chain professionals were using AI by the end of 2024, and an additional 54% predicted adoption within five years, according to the annual report from MHI, a leading trade association for the material handling industry.

How Does Supply Chain AI Work?

AI-powered systems learn from diverse data sources—especially your organization’s internal operational data—to provide high-quality forecasts, optimize inventory levels, improve transport planning, and more. These systems become more valuable to supply chain managers as they continuously gather new data and refine their analyses and recommendations. Conversational AI chatbots act as always-on virtual assistants to supply chain managers, ready to answer questions and surface insights.

As of the mid-2020s, AI supports supply chain operations through several core technologies, including:

- Machine learning (ML): ML is AI’s method of learning from data and improving its own performance without continual recoding. Using ML, businesses can optimize sourcing and operations by analyzing past and present data to identify inefficiencies and automate decisions.

- Predictive analytics: One of AI’s core competencies is the ability to use ML to drive predictive analytics and correlate different data sets. Whether it’s customer demand, equipment maintenance, or price fluctuations, AI can help supply chain professionals anticipate challenges and opportunities.

- Computer vision: Inventory counts, quality control, picking and packing in the warehouse—these and other key functions can be performed rapidly and accurately by AI-powered scanners, robots, and other systems.

- Generative AI (GenAI): GenAI’s content creation capabilities are demonstrating surprising range in supply chain management, from the day-to-day (drafting customer and supplier communications) to the strategic (generating and stress-testing various network scenarios for planning).

- AI agents: This recent innovation in AI uses fit-for-purpose models in such areas as global trade management, dynamic logistics, and supplier contract negotiation. This lets supply chain managers task an autonomous agent with maintaining safety stock, for example—or another high-level directive—and give it the autonomy to plan and execute the many needed steps on its own.

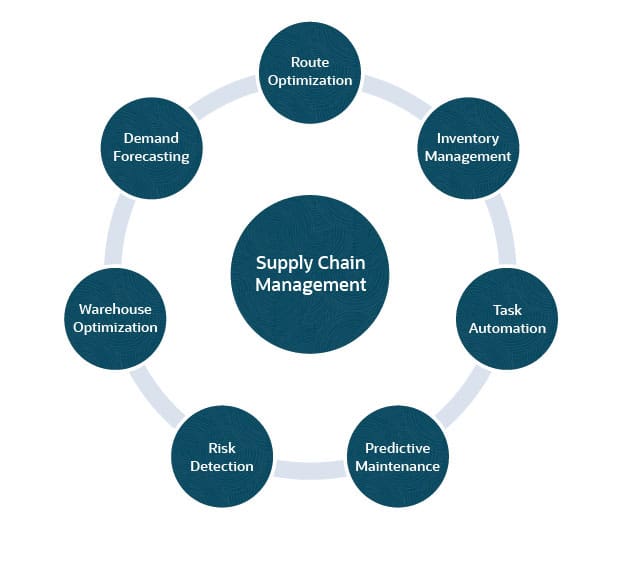

Uses of AI in the Supply Chain

Two-thirds of early adopters of AI in the supply chain report a big impact in many areas, including supply chain planning and inventory optimization, logistics planning and execution, order management, and risk simulation/identification, according to a report from PwC. Let’s take a closer look.

Inventory Management

Inventory management ranks as the top near-term application of AI in the supply chain, according to MHI’s 2025 report. AI-powered systems can improve demand forecasting to stock the right amount of inventory and automate counts and quality control with robots and scanners. They can estimate safety stock levels and suggest when to reorder based on trigger levels—and even adjust those trigger levels as market conditions change.

Route Optimization

AI analyzes warehouse locations, transport links, and other factors to dynamically optimize supply chain routing for shorter delivery times, lower costs, and reduced carbon emissions. Using GPS and other data, AI tools can continually update routes to account for changing conditions, such as traffic, weather, shipping costs, and tariffs.

Demand Forecasting

Supply chain managers are switching from historically based demand forecasting to more forward-looking models powered by AI. The technology identifies early indicators of demand shifts through analysis of social media trends, competitors’ pricing, and other market factors, and can correlate data from multiple sources for more accurate forecasts—like predicting that a competitor’s product recall, combined with rising social media sentiment and upcoming seasonal events, signals an unexpected surge in demand for your alternative product.

Predictive Maintenance

AI can help make maintenance predictive instead of preventive or reactive. Relying on continuous streams of sensor data, AI tools can pinpoint when equipment is likely to fail based on vibrations, temperature, energy consumption patterns, and other factors—improving manufacturing metrics and supply chain reliability.

Warehouse Optimization

Where customer expectations for speedy delivery intersect with today’s labor shortages and supply chain disruptions, warehouse and distribution center managers are rising to the challenge with AI. They’re using it to improve inventory tracking accuracy, implement automation, optimize facility layout, and enrich existing warehouse management software. Consider the AI-powered crane. Instead of following preprogrammed commands, such as moving a pallet from a specific slot, it can identify a better slot for a high-demand item and then put it in the most accessible location.

Task Automation

AI advances workflow automation from simple rule-based bots to intelligent agents capable of handling more dynamic work. While rule-based automation handles repetitive tasks like order processing and invoice matching, AI assistants offer intelligent responses to unique customer and supplier queries in real time.

By 2026, 76% of chief supply chain officers predicted that their process efficiency will be improved by agents, according to a survey co-authored by IBM and Oracle. In one application, GenAI is being used to automatically draft complex procurement documents, summarize live supplier performance data into clear narratives, and create proactive communications to customers about potential delays.

Risk Detection

Three-quarters of supply chain leaders expect the rate of high-impact disruptions to continue increasing, according to one industry survey. AI’s strengths in pattern recognition and anomaly detection make it effective at detecting those risks in real time. Because AI-powered systems learn what “normal” operations look like, they can see when things are going awry and alert supply chain managers to pricing spikes, transportation bottlenecks, or other disruptions.

Top Uses for AI in the Supply Chain

Advantages of Using AI in the Supply Chain

Using AI in the supply chain can put companies on better competitive footing. Supply chain managers can squeeze out unnecessary costs by simplifying complex networks and automating cumbersome functions, all while preserving product quality. They can anticipate risks and opportunities, make better decisions faster, and seize market upsides while protecting against downsides. Specific advantages include:

- Increased supply chain accuracy: AI-powered systems increase accuracy by aggregating real-time data from multiple sources, identifying emerging patterns, and spotting anomalies. AI can cut forecast errors by as much as 50%, saving money through better safety stock management and reduced waste.

- Improved visibility along the supply chain: About three-quarters of those using AI today say it delivers better supply chain visibility across supply and logistics partner ecosystems, according to the IBM-Oracle survey. These models collect and analyze data from many sources, amassing it all into what’s called a supply chain control tower, letting supply chain managers orchestrate operations with dashboards that reflect a single source of truth about what’s going on.

- Enhanced inventory management: By applying AI to inventory tracking, layout optimization, and automation, companies can boost throughput, reduce labor dependency, and improve accuracy in daily operations.

- Lower operating costs: McKinsey & Company found that wholesale distributors that embedded AI enjoyed reductions of 20% to 30% in inventory levels, 5% to 20% in logistics costs, and 5% to 15% in procurement spending.

- Fewer defects, less waste: Computer vision systems continuously monitor production lines and goods for defects with speed and accuracy, catching even microscopic flaws. This not only improves final product quality but also identifies errors early, before more value is added.

- Better employee safety: Injuries from lifting and moving boxes and equipment are among the biggest workplace health and safety issues. AI can create safer work environments as autonomous robots handle more hazardous work and AI-powered cameras monitor for unsafe behaviors and collision risks between workers and machinery.

- Added real-time insights: With GenAI, supply chain managers can update models themselves using plain English, cutting decision time from days to minutes.

- Optimized warehouse layout: GenAI can create and simulate multiple potential warehouse layouts to model the flow of goods, workers, and robots for maximum throughput and productivity.

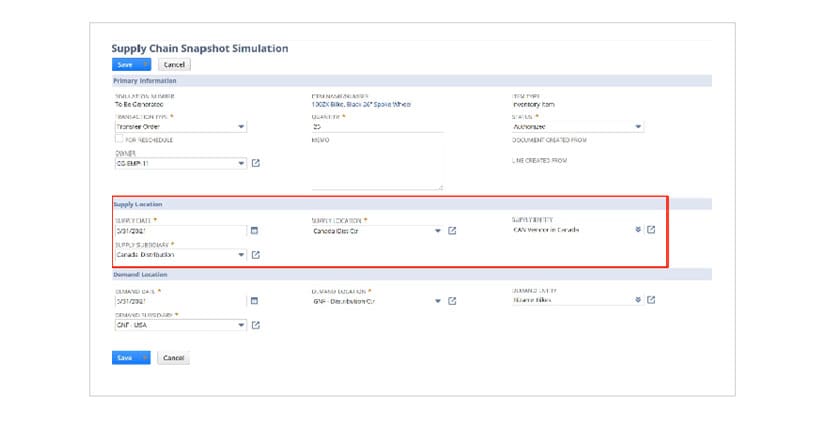

NetSuite Supply Chain Tower Dashboard

Challenges and Limitations of AI in the Supply Chain

Despite AI’s potential, significant barriers to adoption persist. According to the MHI report, the top three challenges are lack of budget, unclear business cases, and poor understanding of the technologies involved. Pilots and early implementations have shown AI’s challenges and limitations to include the following:

- Data limitations: Effective AI depends on high-quality, accessible data. When information is siloed in unconnected systems or is inconsistent and incomplete, the insights generated by AI will be flawed.

- Privacy concerns: Supply chains handle sensitive information ranging from customer details to proprietary product specifications. Centralizing this data for AI creates a prime target for cybercriminals. Adding to this challenge is the difficulty companies face in complying with differing data protection laws in various states and nations.

- Project complexity: AI projects require coordinating multiple elements, from defining the right use cases and preparing quality data to selecting appropriate models, managing organizational change, and establishing ongoing monitoring. Integrating AI with existing legacy systems can also be complex, requiring careful attention to model development, data processing, infrastructure, and testing.

- User adoption: Building AI skills and talent is a challenge for many organizations, as are trust issues and concerns about AI replacing jobs. All these can slow AI adoption.

- Startup costs: Though AI promises long-term savings, the initial investment can be substantial. Basic AI solutions may cost $20,000 to $80,000 to deploy, according to the Coherent Solutions consultancy. More capable AI solutions, such as risk management systems, and fully custom projects cost more.

How to Implement Artificial Intelligence in Your Supply Chain in 8 Steps

AI itself is not a strategy. Rather, it’s a tool that can deliver supply chain improvements only if it is strategically deployed. Implementing an AI strategy requires awareness of the following steps and questions to ask along the way:

-

Identify Optimization Opportunities

Think about the most significant sources of inefficiency, cost, or risk in your supply chain—and how AI could fix them. Analysis should go beyond surface-level supply chain shortcomings to understand root causes. It should also broadly span all relevant departments in the company for a complete view.

-

Prioritize Opportunities and Create a Roadmap

Quick wins are good for justifying any technological investment, but long-term digital transformation is also on many companies’ agendas. Some experts advise drafting a documented AI strategy that sets short-, medium-, and long-term objectives; describes what success looks like; and details what needs to be done to achieve it. This prevents inefficient “franken-systems” that hinder scalability and extend payback periods.

-

Ensure Data Readiness

Effective supply chain AI requires accurate and comprehensive data compatible with supply chain management, CRM, and ERP systems, as well as IoT devices, external databases, and suppliers’ networks. Evaluate whether your organization’s data is clean, consistent, relevant, and sufficient for training AI systems.

-

Evaluate Potential AI Solutions

Which AI tool best aligns with the business goals it’s intended to address? Consider relevant features, scalability, compatibility with current systems, and total cost of ownership, including licensing fees, maintenance, and training.

-

Assess and Select AI Vendors

Many supply chain management software vendors are integrating AI into their software, so customers may gain access to AI through upgrades from an existing vendor. In other cases, companies may turn to a new vendor. Either way, choosing an AI vendor is about entering a long-term partnership with a strategic advisor who can help maximize value over time. Conduct due diligence by checking potential vendors’ technical merits, cybersecurity provisions, understanding of your industry, support process, roadmap for future product development, and track record with other customers.

-

Begin Implementation and Systems Integration

Conduct small-scale AI pilots and proofs of concept to overcome reservations about ROI and other doubts. Select a single use case with clear success metrics and analyze the possible outcomes. For example, a team could test an AI-powered routing tool on one delivery corridor to measure reductions in transport time and fuel costs. Careful planning and project management should help to avoid interrupting day-to-day operations.

-

Determine Use Roles and Begin Training

AI changes how an organization’s employees work, so their roles must be redefined to use the tools effectively. Rather than creating new positions, an AI transition mainly modifies existing jobs—employees perform fewer manual tasks and become orchestrators of AI-driven processes. Training should be provided for new skills the workforce will need, such as data interpretation, critical thinking, and managing AI-driven workflows—and it should reach from leadership through front-line teams to build confidence and consistency in AI use.

-

Launch, Evaluate, and Monitor

AI deployments should be routinely measured against detailed key performance indicators (KPIs) and ROI expectations. AI KPIs for different supply chain applications could include forecast accuracy, inventory turnover, and logistics costs, all of which can be compared with a pre-AI baseline. Ongoing monitoring is crucial to detect any performance degradation that could signal a need for retraining. For example, as fundamental changes occur in a company’s market, such as the entry of a major new competitor or a “new normal” in consumer habits, a supply chain’s AI may need to be retrained. An example of a retraining trigger might be a drop in demand forecasting accuracy beyond a preset level.

Examples of AI in the Supply Chain by Industry

The following is a collection of mini case studies from EY, the IBM-Oracle report, and McKinsey that attach real-world applications and actual results to the promise of supply chain AI:

- Retail vendor negotiation: A leading US retailer and a European shipping company use GenAI bots to automate cost and term negotiations with their vendors. This has reduced negotiation times, lowered procurement costs, and resulted in higher vendor satisfaction, with more than 65% of suppliers preferring to negotiate with the bot.

- Manufacturing trade compliance: A large manufacturer uses AI-powered software to automatically generate complex customs declarations and manage the paperwork for trade incentive programs. This speeds up customs clearance, reduces manual work, and saves significant money on import taxes while maintaining legal compliance.

- Construction inventory management: A major building products distributor uses an AI-powered control tower to proactively manage inventory throughout its network. This system has improved fill rates by 5% to 8% by identifying potential stockouts early and using a GenAI chatbot to provide real-time answers to inventory questions.

- Logistics warehouse productivity: A top US logistics company uses a proprietary AI platform to optimize picking routes inside its warehouses. The system has boosted workforce productivity by about 30%, and a GenAI component allows managers to conversationally query the system to find and fix broader network inefficiencies.

- Virtual warehouse optimization: Another major logistics provider uses an AI-powered digital twin to simulate and optimize its warehouse operations. By running thousands of virtual scenarios, the system has identified ways to increase the capacity of its existing warehouses by nearly 10%, avoiding the cost of acquiring new real estate.

Future Trends of AI in the Supply Chain

AI is rapidly moving supply chains from reactive to proactive. Industry analysts expect supply chains to become largely autonomous by 2035, driven by converging technologies including GenAI, autonomous vehicles, advanced robotics, and sophisticated collaboration platforms. Among the key emerging trends are:

- Adaptive, self-healing networks that automatically detect disruptions, evaluate alternatives, and execute corrections with minimal human intervention—moving beyond prediction to real-time adaptation.

- Digital twins evolving from visualization tools into predictive systems that forecast disruptions, simulate thousands of scenarios, and autonomously optimize network performance.

- AI agents that handle complex, multistep workflows with minimal prompting—negotiating with suppliers, adjusting pricing based on market conditions, and orchestrating entire logistics sequences autonomously.

- Physical operations that become increasingly autonomous and self-directed—for example, with driverless trucks running long-haul routes and AI-powered warehouse robotics.

Supply chain professionals will be called upon to lead this transformation by standardizing processes, improving data quality, driving integration and collaboration, and adopting technologies that deliver measurable business value. The demand is growing for professionals who understand both traditional supply chain dynamics and emerging technologies like AI.

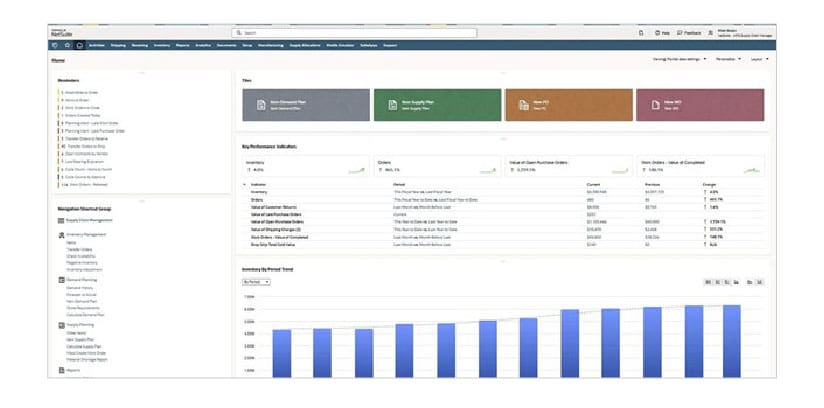

Supercharge Your Supply Chain With AI-Powered ERP

NetSuite Supply Chain Management provides AI-powered predictive insights and intelligent automation to supercharge supply chain operations without having to build a complex AI system from scratch. For example, out-of-the-box machine learning models automatically train on a company’s own data to predict critical outcomes—such as which products are at high risk of a stockout. In turn, inventory managers and other supply chain professionals can shift from reacting to problems to proactively preventing them. Furthermore, features like NetSuite Text Enhance use GenAI to automate content creation for purchase orders, while the SuiteAnalytics tool provides a natural language interface for creating reports and turning complex data into actionable insights using conversational prompts.

NetSuite Supply Chain Management Dashboard

From demand forecasting to inventory management, AI is evolving from a niche technology into a core capability for modern supply chain management. The primary goal is to create more predictive, efficient, and resilient operations that can anticipate disruptions and seize market opportunities in an increasingly volatile world. While significant challenges remain, such as project complexity, data readiness, and user adoption, a strategic, step-by-step implementation can contribute to more autonomous, self-regulating supply chains.

AI in Supply Chain Management FAQs

How is AI helping supply chains?

AI can help supply chains become more efficient, resilient, and intelligent. Supply chain managers use machine learning and predictive analytics to create accurate demand forecasts, optimize logistics by finding the most efficient transportation routes in real time, and enhance warehouse operations through automation and intelligent task management.

How much does it cost to implement AI in supply chain?

Basic AI solutions, such as recommendation systems that use pretrained models, may cost between $20,000 and $80,000 to deploy. More capable prebuilt solutions, such as a risk management system, can cost up to $150,000 and fully custom projects range higher.

What are the pros and cons of AI in supply chain?

Primary advantages of AI in the supply chain include lower operating costs from optimized inventory and logistics, improved visibility across entire networks, and the ability to anticipate risks and opportunities to make better, faster decisions. Main challenges include high startup costs, the complexity of integrating AI with older legacy systems, and data limitations if a company’s information is incomplete or siloed. User adoption can also be a hurdle if employee skills and buy-in are lacking.

How can AI make supply chains more sustainable?

AI can make supply chains more sustainable by optimizing operations to reduce waste and carbon emissions. For example, AI-powered route optimization finds the most fuel-efficient delivery paths, directly lowering a fleet’s carbon footprint. In warehouses, AI helps minimize energy consumption by intelligently managing lighting and HVAC systems and reduces waste through optimization of packaging and inventory levels to prevent overstocking. In addition, AI can continuously monitor and analyze data from global sources to assess supplier sustainability and ethical track records, allowing managers to judge whether partners maintain an expected level of environmental responsibility.