Slow-moving inventory is a problem many businesses deal with from time to time. The challenge is knowing what to do about it, since the reasons sales may slow for a particular product can vary significantly — and the solution must match the cause. Knowing how to identify slow-moving products in your business, find the underlying cause and address the problem is an important skill set to have when selling physical products.

What Is Slow-Moving Inventory?

Slow-moving inventory is inventory that's taking a long time to sell. That may sound too vague to be helpful, but truth is that "slow-moving" is going to be defined differently for different industries, companies, and even for different products within the same company. Common definitions say things like, “inventory that's been in stock for over X days” where X is usually 90 or 120 or 180. But a business selling baked goods or dairy products certainly can't keep items on shelves for 80 days and expect them to remain viable for sale.

Even some companies whose products don't spoil can't wait 90 days to determine whether inventory is slow-moving or not. If a company knows roughly how many units it should be selling each week or month, it can look at the rate of sales for a product instead of time spent in inventory, which will give it an earlier heads up than inventory metrics. This method of identifying slow-moving inventory can be trickier, though, because there's not a convenient hard cutoff. Companies that go this route put boundaries in place like, "Trigger an alert if sales go Y% below the slowest sales month for this product in the last two years" or — if the company is confident about its demand forecasting abilities — “Anything more than Z% below the bottom of our forecasted sales range.” These are the main ways of defining and identifying slow-moving inventory; other ways are discussed below.

Slow-Moving vs. Obsolete Inventory

Obsolete inventory, sometimes called "excess inventory" or "dead stock," is inventory that customers don't want and the business believes it won't ever sell. At first, it can be hard to tell if inventory is slow-moving or becoming obsolete, and often a product that becomes obsolete will spend some time as slow-moving inventory first. Think of technology products when a new version comes out. Most people will want the new one, but some will prefer the old one because it's familiar or to save money. That old model may have just become slow-moving. But fast-forward another technology generation or two and that model may be completely obsolete.

Key Takeaways

- Inventory can become slow-moving for a variety of reasons, from changing seasons to tougher competition, poor marketing or deteriorating sales channels.

- When responding to slow-moving-inventory, finding the underlying cause is the most important first step — each possibility listed in the previous bullet requires a different response.

- Good inventory management software is indispensable to every step of slow-moving inventory solutions — identifying which products are moving slowly, figuring out why and crafting the appropriate response.

Slow-Moving Inventory Explained

A business could find its inventory moving slowly for a number of reasons. A new competitor or substitute for a product could be drawing customers away. If the business sells big-ticket items like cars and refrigerators, economic downturns and anxieties can cause customers to delay purchases. A product that was once "hot" may go out of fashion or be replaced by another. Offers may become uncompetitive over time, or a business's tried-and-true marketing channels may no longer reach its customers — for example, if its customers are aging but it is still marketing through the channels that reached them when they were young.

It's important to identify the cause of slow-moving inventory for two reasons. First, the cause may suggest a solution. If marketing isn't reaching the right customers, that requires a different solution than if prices are too high. Second, the slow-moving inventory may just be an artifact of how the business identifies it. For example, if your business has a rule that inventory taking more than 90 days to sell is slow-moving, but 91 days ago a supplier offered a fantastic deal on a huge bulk purchase, you may have pushed that product category into the "slow-moving" definition on purpose by securing a great price and being willing to hold onto more units to sell over a longer period of time. In that case, sales may not have slowed at all; it's just that you made a decision that rendered the 90-day rule inappropriate.

Why Is Slow-Moving Inventory Problematic?

Slow-moving inventory can be problematic in a few ways. It can be a direct problem, as it ties up capital and storage space that could potentially be better used on other, faster-selling products. Having slow-moving inventory also carries some risk, as the longer a business holds on to stock, the more opportunities there are for the product to become obsolete or for the market value of the stock to decline or, in the case of perishables, for the inventory to expire and become worthless.

Slow-moving inventory can also point to other problems. If inventory is slow to move because the company bought too much, there may be an issue with demand forecasting. If inventory is slow-moving because the company is losing business to competitors or substitutes, the business may have become less competitive. The company has some work to do to find out why, and the simplest approach to this is to research competitors' offerings and/or ask current and former customers about their purchase decisions.

There's also slow-moving inventory that is planned for, which isn't a problem at all, as in the example above of placing a large bulk order to receive a discount. But when slow-moving inventory comes as a surprise, it usually means there's a problem worth uncovering.

Impact of Slow-Moving Inventory

There are several possible ways that slow-moving inventory can affect a business. Being aware of them can help businesses navigate smaller issues before they become bigger problems. Slow-moving inventory can:

- Tie up capital. Buying inventory can be expensive. Inventory sitting on shelves and in storage for long periods of time represents dollars that could have been more effectively spent elsewhere.

- Cost more to carry. Storing extra inventory is a considerable expense for some businesses. If items need refrigeration or more space than you have, that increases carrying costs even more.

- Lose value. The longer an item sits unused and unsold, the greater the chance that its value will decline. A new model coming out or changing fashions and styles can turn a hot commodity into something hard to sell. Perishable inventory loses all its value when it expires.

- Risk obsolescence. If a company sits on inventory too long, it could become obsolete and its value could decline to zero (or close to it). A never-opened 20-year-old computer is technically more usable than a quart of sour milk, but the two have functionally the same value to a modern retailer.

- Get lost or stolen. Disasters like floods and fires can wipe out inventory, and theft is also a concern. The more value a business has sitting in inventory, the greater the potential loss from such an adverse event. Theft, of course, is a bigger risk for businesses selling something valuable — jewelers have a greater risk here than bakeries.

- Indicate another problem. Slow-moving inventory may not be the issue actually impacting the business, but it could be indicating a problem elsewhere. When thinking about slow-moving inventory, it's very important to ask why the inventory is slow-moving. Without knowing the why, you'll never know what to do about it.

How to Identify Slow-Moving Inventory

No single definition of slow-moving inventory provides a bulletproof way to identify that a problem exists. A business might flag inventory as slow-moving when it isn't a real problem, and another may be in a position to identify a problem before its chosen inventory metric crosses the threshold where it triggers an alert. To identify issues early and accurately, it's useful to know and monitor the following seven ways of identifying slow-moving inventory.

Overstock:

Too much stock of a particular item can be the result of slow-moving inventory. Businesses can monitor potential overstock situations by tracking how long items have been in inventory and/or tracking absolute levels of inventory. If a business has a contract where it's buying a fixed amount of something at regular intervals and its inventory starts to rise over time, that could mean that sales have slowed down.

Inventory turnover:

Inventory turnover is a common financial metric that measures the speed with which a business is selling its inventory, but it's a measure that usually combines product types and measures everything in dollars. Good inventory management software can calculate inventory turnover for individual products, which will be a much clearer flag for signaling what is selling slowly and what isn't.

Shipment frequency:

This metric can be used on both ends of inventory management. If the business automatically reorders when stock gets below a certain level, track how often shipments are received. If the rate slows down, that usually means inventory is selling more slowly. It's also possible to track the frequency of customer shipments as a proxy for the rate of sales, though you don't necessarily want to count big shipments the same as small ones.

Holding costs:

If a business is spending more and more money in inventory holding costs, that's a good sign it's ordering too much (unless the inventory increase is purposeful). If holding costs increase but the business hasn't changed its ordering behavior, that usually means sales have slowed down.

Average days to sell inventory:

Like inventory turnover, average days to sell inventory is usually a blended financial metric of limited use in identifying a specific product that's selling more slowly (unless the business sells only one product). It measures how many days, on average, it takes to generate sales equal to the value of the inventory, but that could mean some products sell out and get reordered multiple times while others don't even sell out once. Calculating a modified version of this for each product and tracking it over time, however, can be revelatory. Good inventory management software can do this.

Gross profit:

This is one of the highest-level views of a business, but to monitor adverse events that hurt the business, tracking gross profit over time is how to do it. A downward fluctuation in weekly gross profit won’t by itself indicate slow-moving inventory, but, combined with other metrics, it can indicate whether slow-moving inventory (or another potentially unfavorable situation) has become a problem.

Inventory forecasting:

One of the more interesting ways to measure slow-moving inventory is to compare how quickly each product is selling against the forecast for how quickly that product would sell. This is especially useful when sales volume is volatile, because comparing this week's or month's sales to the one before isn't very telling in that situation. A company with good inventory forecasting may find that forecasts are a better measure than pure historical data or experience regarding where inventory levels should be; if the forecasts start becoming consistently and increasingly wrong in the same direction over time, that could be a sign that something has changed in sales.

The ideal way to track all of these metrics is to automate their regular distribution to relevant business stakeholders through the use of best-in-class inventory management software. Such a system should also be capable of sending special alerts whenever one of these metrics crosses a predefined threshold.

What to Do With Slow-Moving Inventory

Once a company realizes it has inventory that's slow-moving, the question becomes what to do about it. There are many possible responses to slow-moving inventory, but not all strategies are appropriate for all causes. Here are a few strategies for dealing with slow-moving inventory, coupled with when they might be most appropriate.

-

Cut prices (permanently or temporarily).

This is not usually a business's first move but is first on this list because it's the most straightforward and addresses the problem head-on. To the extent that the market for a product is governed by basic supply and demand, lower prices should increase sales. Offering a product at a sales discount can be a way to temporarily cut prices if the sales slow-down might be temporary. If the business is trying to sell out of a product before it becomes obsolete, or if a competitor has lowered prices to acquire market share, then more permanent price cuts may become necessary to increase the speed at which inventory can be sold.

-

Improve product attractiveness.

Sometimes inventory isn't selling quickly because customers aren't drawn to it or they are reacting negatively to the way it's marketed. There are a variety of ways businesses can combat this, including:

- Improving website navigation to make the product more prominent.

- Enhancing photo quality and marketing copy on the website.

- Using search optimization to improve the product's web page rank.

- Moving the product to a more prominent place in stores.

- Revamping product packaging/display.

-

Offer promotions.

This is a way to offer customers more economic value without making a precedent-setting price cut. "Buy one get one free" or "Buy one get one 50% off" is a temporary way to move inventory more quickly, but make sure profit margins can sustain customers taking advantage of the deal to the fullest. You can also offer other kinds of promotions, including discounts on other products, early access to your next new product or less expensive freebies. For example, when Microsoft was trying to sell Surface Pro 2 tablets right before the Surface Pro 3 came out, some stores offered free screen protectors, cases and even Microsoft T-shirts to help sell off their slow-moving and about-to-be-obsolete inventory.

-

Leverage channels.

This approach will look very different by industry, but sometimes there are sales channels businesses can use to sell inventory faster, leveraging partners with access to more (and more diverse) customers. This is especially valuable if the slow-moving inventory is due to marketing efforts not reaching enough or the right people. These channels can include selling on an online platform as a third-party seller (Amazon is the most common platform these days), partnering with a company to offer its customers a deal (Costco is an example of a retailer with many partners, both long- and short-term), putting stores on a delivery app like DoorDash or Instacart and joining with websites that share deals.

-

Donations.

If a business needs to shed inventory faster than it can sell it, there may be a way to donate it. This doesn't generate revenue, but it might be a useful tax write-off — and having inventory do some good in the world is better than having it decline to zero value on a shelf and get thrown away. Donations can also generate goodwill in communities, as well as good media coverage. Many companies overlook this option because they don't have an employee whose job it is to arrange donations, but it's an underappreciated way to recover value from overstocked goods that aren't selling.

-

Provide useful content.

Particularly for ecommerce, a blog with good content can bring in readers, and if the article topics relate to the problems your products solve, the readers you bring in will have a lot of overlap with your target customers. When sales of a particular product slow down, blog posts can specifically target readers who might also be target customers for that product.

Examples of Slow-Moving Inventory

Slow-moving inventory happens for many reasons, so organizations must use different methods to try to identify the situation as early as possible. Here are a few examples that illustrate these variations. Note that each case has three steps:

- Identify the slow-moving inventory problem.

- Diagnose the cause.

- Choose a remedy based on the cause.

Example 1: Dishwashers.

Jack runs a company that sells dishwashers and other major appliances. He keeps at least a few of each kind on hand to meet demand, and since it's logistically more efficient to place larger orders with his suppliers, Jack's dishwashers tend to stay in inventory for up to four months before being sold. He starts noticing, however, that a lot of his stock has been on hand for five months. Dishwashers have become slow-moving inventory. Why is that?

Jack does some digging. His prices are the same or better than other sellers'. There's no new model he doesn't carry. And looking at past sales data, there's no typical slump this time of year. Next, he checks other expensive appliances in stock and discovers that refrigerators and washer/dryer sets are also selling slower, though just well enough that they have yet to trip his slow-moving inventory alert. This leads Jack to realize that economic conditions are causing customers to delay making large home purchases. Offering dishwashers through more channels or improving their display in the store won't help here, so he decides to offer a solution targeted at his customers: an extended warranty and discounts through periodic sales.

Example 2: Cloth masks.

In early 2020, Jane's cloth face mask business really took off and she rapidly increased production to meet demand. After six months, though, Jane discovers she has excess inventory that isn't selling as quickly as before, as measured by daily and weekly sales (which she checks every day). It's a clear pattern. And yet, demand for masks hadn't gone down in general. After doing more research, Jane realizes that her competition has simply passed her by. Her website traffic dropped from record highs, down to average levels. Customers still wanted her products, but they were finding her new competitors first.

Jane addresses the cause by investing in search engine optimization for her website and buying ads on social media sites. She also improves the appearance of her website to keep pace with the competition. Her problem had nothing to do with her product or the demand for it; it was about her ability to find and communicate with potential customers. In this case, not only was there no need to lower prices, but doing so would have likely had little impact on sales.

Example 3: Coats.

Amelia's boss comes into her office in a panic. "We have inventory that's been in stock for five months that's supposed to sell out in 90 days! And our gross profit on these items has plummeted! You're our inventory manager. How did this happen? And fix it!"

"What item specifically is the problem?" asks Amelia.

"SKU 84471" says her boss, reading off a Post-it Note.

Amelia smiles. "Those are winter coats, and it's August. The problem will sort itself out in a few months."

The point here is that not every case of slow-moving inventory is a problem that needs to be solved. Amelia's boss learned a valuable lesson about not managing by simple metrics and spreadsheets alone.

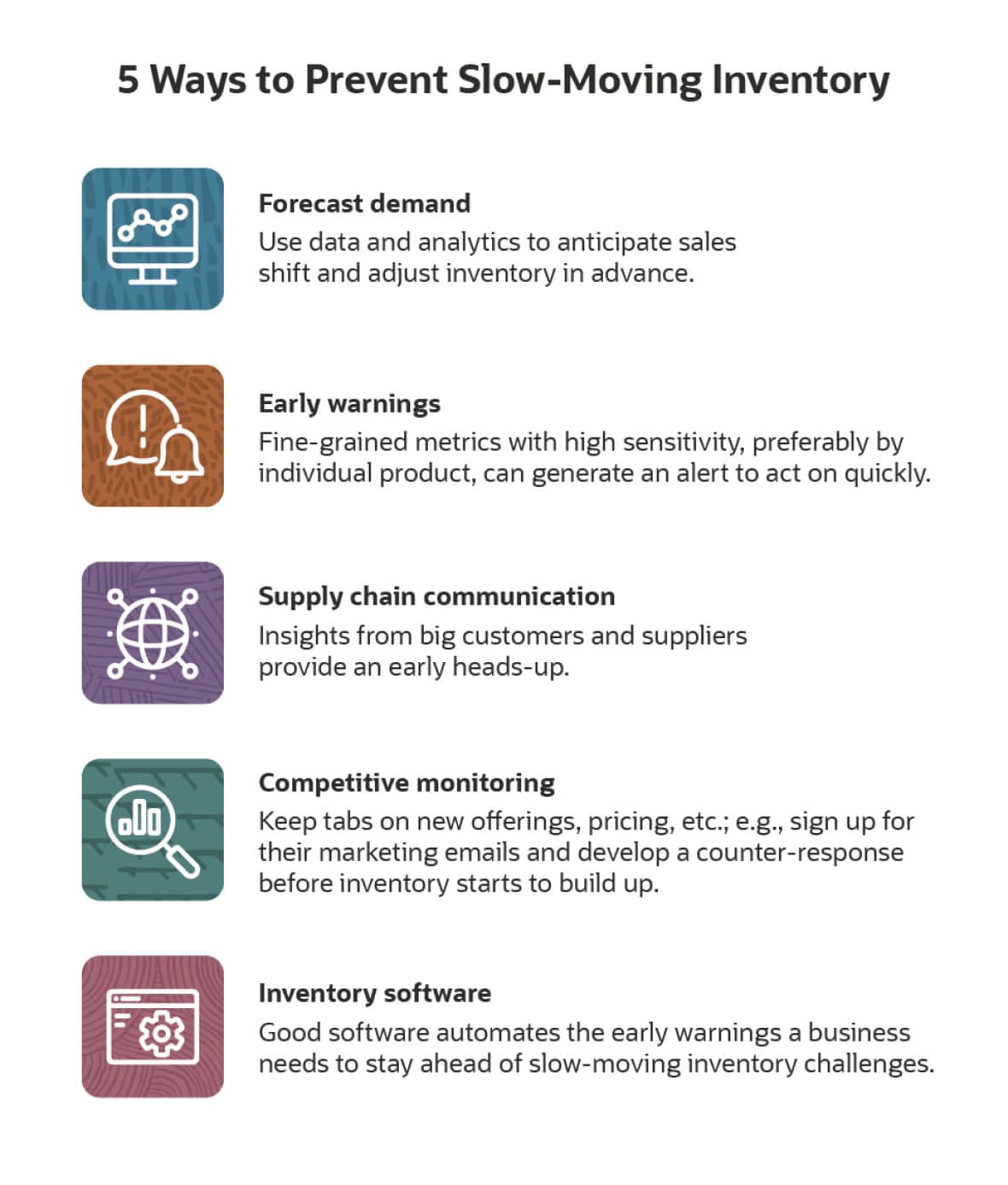

5 Ways to Prevent Slow-Moving Inventory

Often the best way to address slow-moving inventory is to avoid having any to begin with. Here are five ways businesses work to prevent problematic slow-moving inventory:

-

Forecast demand:

Good demand forecasting can provide an early warning of when sales will drop, and inventory can be adjusted accordingly. For example, if the business sells winter clothing and predictions foretell a mild winter, use past years' sales data combined with weather history to figure out how many fewer of the heaviest coats will sell.

-

Early warning systems:

If the business can identify its slow-moving inventory, it can monitor its metrics and set alerts that are more sensitive than the planned threshold values. Before crossing the line into slow-moving inventory, the business can follow cautionary metrics that permit preventative action. For example, if slow-moving inventory is defined as inventory that has spent 90 days in stock and products typically spend between 40 and 80 days in stock, knowing that a 40-day product has drifted up to 70 would be very valuable information, even if it hasn't yet crossed the alert threshold.

-

Supply chain communication:

Good communication with their biggest customers and suppliers will help businesses make better predictions and adapt faster to changing circumstances. For example, being able to tell a supplier to delay a regularly scheduled shipment because a customer warned it might not need as much product during the next quarter could spell the difference between ending up with slow-moving inventory — and not.

-

Monitor the competition:

Some causes of slow-moving inventory involve competitive forces — namely, better deals and newer products being found elsewhere. Actively monitoring competitors can help a business deal with new challenges proactively instead of discovering them, too late, by diagnosing a tangible new problem. For example, signing up for a competitor's marketing emails will provide real-time data on when they have sales and are planning to launch a new product, allowing you to respond immediately instead of waiting for sales to sink.

-

Inventory management software:

Good software helps businesses stay on top of inventory and sales in real time, without having to wait 90 or more days to make backward-looking observations, and without having to go on a fact-finding mission to calculate metrics and measure speeds. An inventory management software system that presents the supply chain in detail allows businesses to make small adjustments and corrections to prevent big problems from ever occurring. For example, if customer tastes are changing and consumers are now buying more funny possum T-shirts and fewer funny cat T-shirts, you can adjust your orders accordingly based on real-time sales data, instead of waiting until you're all sold out of possum shirts and have an excess supply of cat tees.

Manage Slow-Moving Inventory

Managing slow-moving inventory sometimes becomes a cost-benefit analysis. How much does it cost to keep this inventory on hand? How big a problem is it? Will the problem eventually go away if left unaddressed? There are a number of possible remedies for slow-moving inventory, as discussed above, many of which come with costs in both money and time. Some of the costs continue to provide a return on investment long after the slow-moving inventory problem is solved (like improving the website), while others offer no residual value (like discounts offered through partner-run sales channels).

A good inventory manager is going to know what solutions could be brought to bear on the problem, but also how much is worth spending. Sometimes slow-moving inventory can be addressed by waiting (and maybe postponing the coming order) if it's due to over-ordering something once. Sometimes slow-moving inventory is in danger of expiring or becoming obsolete, and more aggressive measures are necessary. In between, inventory managers must weigh various factors and estimate which approach saves the most time and money. A company with ample warehouse space and durable products that aren't in danger of becoming obsolete (for example, bookshelves) is in a much better position to hang on to slow-moving inventory and ride out a slow cycle than a company dealing in electronics that go obsolete quickly or food products that expire even faster.

Save Money and Time With Inventory Management Software

It's almost impossible for a growing business to be proactive about slow-moving inventory without inventory management software. Companies that don't have such a system in place are almost always playing catch-up, looking at situations after the fact and monitoring at much less frequent intervals. With good software, businesses can get an accurate and real-time picture of their inventory every day, along with updated metrics they can use to look out for inventory that may be slow-moving or trending in that direction. NetSuite Inventory Management provides all these capabilities and scales with businesses as they grow. Furthermore, it integrates with other enterprise resource planning (ERP) system modules like demand forecasting, which helps businesses become more proactive, addressing potential slow-moving inventory problems before they have a chance to manifest.

Conclusion

Slow-moving inventory is a common issue that many businesses face from time to time. Sometimes it's a problem; sometimes it indicates there's a problem elsewhere; and sometimes it's just part of a strategy of stocking up on extra inventory (e.g., to secure a good price or reduce the risk of a shortage). The key to handling slow-moving inventory is to have good strategies in place for identifying it, diagnosing the cause and crafting an appropriate response. Good inventory management software is usually crucial to solving all three scenarios.

Award Winning

Cloud Inventory

Slow-Moving Inventory FAQs

How should ecommerce handle slow-moving items?

There are a number of strategies for handling slow-moving inventory, but an ecommerce business in particular needs to constantly check that its customers can find its products easily. Unlike physical stores, the "location" of a digital store changes for customers that navigate by search results. Using search engine optimization (SEO) techniques and making sure descriptions and pictures are accurate, helpful and attractive are essential for ecommerce retailers to stay relevant and visible to customers.

What is non-moving inventory?

Non-moving inventory is another name for obsolete inventory, which is inventory the business doesn't expect to ever sell. It may have expired (like a moldy loaf of bread), been rendered obsolete (like 1990s cellphones) or even become illegal (like over-the-counter cocaine products in pharmacies).

How do you move slow inventory?

Slowly. Next question ... More seriously, letting it move slowly is an option if remedies are more expensive than waiting, but strategies for drawing down inventory more rapidly include promotions, discounts, price cuts, marketing improvements in communication and packaging, better search engine optimization for online sales, leveraging channel partners' access to customers and even donating excess inventory for a tax write-off and goodwill.

Why may you have slow moving items?

Slow-moving inventory can occur for many reasons. For example:

- You ordered too much, perhaps to take advantage of a bulk discount or because you anticipated a spike in demand that never happened.

- The product is falling out of favor with customers (either seasonally or for the long term).

- Economic anxieties are causing customers to postpone purchases.

- A competing product or substitute is drawing customers away.

- Competitors are offering better deals.

- Your search engine ranking may have declined as other websites optimized their content.