Manufacturing companies often spend weeks or months searching for the right employees—a time-consuming process of recruiting new candidates, combing through resumes, and squeezing in interviews, all while struggling to meet production deadlines. However, once the new hires are properly trained and starting to get the hang of the company operations, many will seek other opportunities elsewhere—and the business finds itself right back where it started: short-staffed, behind schedule, scrambling to recruit new workers, and hoping to lift the morale of remaining team members.

Indeed, retaining talent in the manufacturing industry is tough—and it’s particularly challenging when employees have to wrestle with difficult working conditions or limited growth opportunities. So, how can manufacturers stop the churn and build a loyal long-term workforce? This article breaks down the causes of high employee turnover in manufacturing and provides effective strategies companies can implement for significantly improved retention rates.

What Is Employee Retention in the Manufacturing Industry?

Employee retention in the manufacturing industry refers to a company’s ability to keep skilled workers employed over time for minimal turnover and a stable, experienced workforce. High retention is crucial in manufacturing because it preserves institutional knowledge, facilitates consistent productivity and product quality, and reduces the costs and disruptions associated with recruiting and training new employees. Given the physically demanding, and sometimes repetitive, nature of manufacturing work, effective retention strategies, such as competitive compensation, ongoing training, flexible scheduling, and a positive work environment, are essential for sustaining operational efficiency and long-term business success.

Key Takeaways

- The consequences of high employee turnover in manufacturing include decreased productivity and missed deadlines.

- The manufacturing industry is expected to need more highly skilled workers in the upcoming years.

- Limited career growth opportunities and rigid workplace policies are two of the main causes of high turnover in manufacturing.

- Top strategies for retaining manufacturing workers include improving onboarding processes, fostering a collaborative culture, and investing in employee recognition.

Employee Retention in Manufacturing Explained

A recent Manufacturers Alliance survey found that 78% of member companies had a voluntary turnover rate of 10% or more among hourly workers, and 22% saw a turnover rate higher than 20%. Given the sheer number of departures facing companies, it’s no surprise that more than 65% of manufacturers said in 2024 that attracting and retaining talent is their primary business challenge, according to the National Association of Manufacturers.

Workforce challenges in manufacturing are nothing new; employee turnover rates have been elevated for years. In February 2025 alone, US manufacturers saw 184,000 workers quit, according to the Bureau of Labor Statistics. As a result, the labor market is expected to remain tight during the years ahead. In fact, manufacturers are expected to need 3.8 million new employees between 2024 and 2033. And, as production operations become more complex and manufacturers increasingly use advanced technology to streamline their operations, the industry will likely see a greater demand for highly skilled roles, in addition to traditional production roles. The general expectation is that manufacturers will need more mechanical and industrial engineers, software developers, information systems managers, and computer analysts.

Since competition for positions can be intense, manufacturers should make changes now if they want to remain fully staffed in the years ahead. About 1.9 million open jobs could remain unfilled through 2033 if manufacturers don’t successfully address the skills and applicant gaps, according to Deloitte and the Manufacturing Institute.

Impacts of Employee Turnover

Running a successful manufacturing business demands more than simply hitting output targets and keeping production lines humming along—it requires hard-working people. But when those people leave their jobs faster than a company can replace them, the consequences are numerous: Veteran workers get burned out trying to cover vacant positions. Productivity drops. Teams fail to meet deadlines. Training costs pile up. And the company loses hard-earned institutional knowledge and team cohesion. In short, manufacturers with high employee turnover run the risk of experiencing negative repercussions in the following areas:

- Employee morale: When employees see colleagues leaving regularly, morale often takes a dive. Staff members who remain may start feeling overworked and underappreciated, leading people to become resentful of the company and disengaged in their work. If low morale is left unaddressed, it can create a workplace culture where people are merely clocking in and going through the motions, rather than contributing to their full potential. This prompts more people to flee, thereby exacerbating the turnover cycle.

- Productivity and efficiency: Each experienced worker who walks out the door can leave a negative impact on productivity and efficiency. After all, the company must recruit and hire replacements—and those new hires need to be trained on processes, tools, and safety procedures, all of which takes time. In the meantime, the remaining workforce often struggles to fill gaps in coverage, which can cause delays, increased errors, and a slowdown on production lines. In fact, 89% of manufacturers that responded to a 2024 Quickbase survey said labor shortages were negatively impacting shop floor efficiency.

- Money: High turnover in manufacturing is costly. Recruiting, onboarding, and training new workers, plus paying overtime for those filling staffing gaps, are pricey. Additionally, a company may lose revenue due to reduced output and materials scrapped because of mistakes, and it may even face financial penalties for delayed shipments. All these expenses can erode a manufacturer’s revenue and eat into profit margins.

- Institutional knowledge: When longtime employees leave, they take years of knowledge with them. In manufacturing, some of the most valuable skills are learned on the floor rather than from a training manual or textbook. Effective techniques, shortcuts, troubleshooting instincts, and safety precautions can walk out the door with every departure. If a company doesn’t have strong mentoring programs or knowledge capture processes, newer workers are left to reinvent the wheel, often with less success.

What’s Causing Employee Turnover in the Manufacturing Industry?

While low pay and insufficient benefits are often blamed for employee turnover in the manufacturing industry, deeper issues within the work environment can also be at play. Some of the major factors contributing to rising turnover rates include:

- Poor corporate culture: A poorly managed, uninspiring workplace can drive employees away. In manufacturing, poor communication, lack of trust in leadership, and a “just get it done” attitude without adequate support can make employees feel like cogs in a wheel, rather than valued team members. Ultimately, a poor company culture can cause workers to become disengaged, prompting them to search for new jobs with companies offering a more positive atmosphere.

- Limited career growth: When workers don’t see a future for themselves at a company, they may decide they’re working in a “dead-end job” and head elsewhere. A Deloitte study found that 58% of manufacturing employees believed their jobs had limited career prospects. In many cases, that’s because the company didn’t provide workers with a clear path for advancement.

- Workplace rigidity: Rigid schedules, inflexible workplace policies, and outdated top-down management styles are clashing with the expectations of today’s manufacturing workforce, particularly younger workers who demand more autonomy and a healthier work-life balance. If a company can’t offer flexible schedules or sufficient paid time off, for example, workers may decide to find employers that can.

- Lack of recognition: In a production facility where employees are expected to keep their heads down and grind out orders, managers may forget to recognize hard work—with negative consequences for the company. In fact, a recent Gallup analysis found that only one in three US workers strongly agreed that they received recognition or praise for their work in the previous week. The analysis also revealed that employees who feel routinely ignored are twice as likely to say they’ll quit in the next year.

- Hazardous work environments: Clearly, employees who don’t feel physically safe in their workplace won’t be motivated to stick around. However, despite regulatory oversight, safety remains a serious concern in manufacturing. Employers that use outdated equipment and have poor safety protocols not only put their workers at risk, but they send the message that employee well-being isn’t a high priority. In addition to keeping workers physically safe, employers need to make sure their workforce feels psychologically safe to speak up, share their opinions, and voice their concerns without fear of retaliation. A psychologically safe environment allows trust to flourish between supervisors and workers—and building those bonds in the workplace is key to retaining employees long term.

13 Top Retention Strategies for Manufacturing Businesses

At a time when skilled labor is in high demand, constant employee turnover can stall production and set manufacturers back from hitting their targets. Luckily, businesses can take steps to build a more stable, engaged, and loyal workforce. From improving onboarding experiences and promoting workplace safety to recognizing rising leaders and modernizing the company’s tech stack, each of the following 13 strategies is designed to help reduce turnover, boost morale, and create a work environment that promotes employee satisfaction:

-

Identify and Monitor Your Retention Metrics

Many companies are so focused on the daily to-do list of fulfilling orders that they fail to realize just how many employees are coming and going. Identifying and monitoring employee turnover and retention metrics are critical steps to understanding how many workers leave, why they’re exiting, and what the company needs to change for improved retention.

Manufacturers should use a combination of data tracking, employee feedback, and predictive analytics to closely track key performance indicators, including turnover rate, employee engagement level, and reasons for departure. Conducting regular surveys of existing staff, as well as exit interviews of departing staff, can provide insights about employee satisfaction—and, if they’re unhappy, the company should seek employees’ input about ways to improve the environment. Meanwhile, predictive analytics tools can help flag early warning signs that employees might quit soon—for example, by monitoring a drop in employee engagement scores or increased absenteeism. This data can prompt human resources teams to initiate a conversation about common problems encountered by employees, which leads to greater support that reduces risk of quitting.

-

Make a Good First Impression

A study by BambooHR shows that 70% of new hires decide if a new job is the right fit within the first month of employment—and an alarming 44% have regrets about their new role within the first week. The early days of an employee’s experience can shape their perceptions of a company—and people who feel disconnected, underprepared, or unsupported are less likely to stay.

Manufacturers should create welcoming onboarding processes that do more than help with filling out paperwork and watching training videos. Instead, they should offer structured training programs, assign veteran workers as mentors for new hires, and make sure employees have the space and license to ask any questions necessary during onboarding. Creating opportunities for current staff to mingle with new staff is important. In fact, the BambooHR survey shows that new hires value workplace friendships, with 87% hoping to make a friend at work and 93% wishing to shadow a colleague. Adding personal touches to the onboarding process, such as a team lunch or a welcome package with company swag, can make employees feel valued from day one.

-

Discourage Toxic Workplace Dynamics

A 2025 iHire survey of US workers and employers found that nearly 65% of employees have worked at a toxic workplace, and about 54% have quit due to experiencing this kind of negative work environment. And nearly 79% blamed poor leadership for toxic cultures. A workplace tainted by bullying, favoritism, gossip, or lack of accountability can lead workers to tune out, stress out, burn out—and leave. Discouraging toxic workplace dynamics is especially essential in manufacturing—an industry where teamwork, safety, and morale directly impact overall productivity.

Rooting out inappropriate behavior starts at the top. Business leaders should set clear behavioral expectations, as well as formal policies and training programs that clearly express zero tolerance for disrespect and harassment. They should also train managers on how to be respectful and inclusive without micromanaging and criticizing their employees’ every move. In addition, companies should establish anonymous reporting mechanisms that permit employees to safely speak up should they experience an issue or notice a problem, and leaders should take swift, decisive action to correct any such concerns.

-

Foster a Collaborative Company Culture

Manufacturing relies heavily on team-based workflows, whether on the production floor, in logistics, or among IT staff. Employees who feel connected and valued as teammates towards common goals are more likely to stick with a company. To build a collaborative culture, manufacturers must encourage conversations to flow. For example, a company might develop daily stand-up meetings or regular shift huddles, inspiring team members to discuss challenges, provide updates on their work, and align on goals. Creating team-based incentives, rather than individual ones, such as providing bonuses for delivering orders on time or meeting safety targets, can be another powerful tool for recognizing both individual and team contributions towards a common goal.

In addition, investing in collaborative technologies, including digital scheduling boards, collaboration apps, and employee suggestion programs, can foster a sense of ownership and transparency that benefits the entire workforce. It’s important to note that business leaders need to do more than encourage collaboration; they need to walk the talk by routinely seeking employee input and highlighting team wins.

-

Invest in Employee Recognition

Long hours, repetitive tasks, and a high-pressure work environment with strict deadlines can take a toll on manufacturing workers. To improve retention rates, it’s essential for companies to boost morale through employee recognition programs. In fact, a recent Workhuman and Gallup report found that employees who say recognition is an important part of their organization’s culture are 3.7 times as likely to be engaged, 3.8 times as likely to feel connected to the company’s culture, and 50% less likely to experience frequent burnout than those who don’t feel recognized. However, the same report found that only 34% of employees say their employers have a recognition program in place, and among those with one, only 13% rated the program as excellent.

To recognize employees’ hard work in meaningful ways, manufacturers can develop peer-to-peer recognition programs, send real-time shout-outs to acknowledge consistent efforts, and link recognition to meeting company goals. Examples of programs include a “team member of the month” award or extra paid time off for hitting production or safety benchmarks.

-

Empower Potential Leaders

Rewarding the most efficient and productive workers by adding desirable responsibilities, such as overseeing operations or spot-checking another team’s output, can show employees that it’s possible to grow into leadership roles within the company. Manufacturers should start by identifying employees with leadership potential through performance reviews, peer feedback, and observational assessments. Companies can then offer structured leadership training programs, including in-house workshops, online certifications, and mentorship tracks potential leaders are paired with experienced managers to learn strategies for managing others. Also, allowing employees to handle certain higher-level tasks, such as leading a team meeting or managing a group project, can build confidence and loyalty while helping prepare people for broader leadership roles as they become available.

-

Prioritize Workplace Safety

When workers don’t trust that their employers are doing everything possible to maximize safety, they aren’t likely to stick around long term. In fact, a 2024 Vector Solutions survey found that safety is the second-most-important factor determining whether industrial workers remain on the job (second only to pay). Furthermore, 46% of workers said their employers could be doing more to reduce safety incidents, and 83% complained that their company’s safety protocols felt like mere checkboxes rather than genuine commitments to protecting the well-being of employees.

Manufacturers can emphasize to staff that safety is a high priority in a variety of ways, such as conducting regular safety training and refresher courses for specific roles and equipment, encouraging confidential and immediate reporting of potential hazards, utilizing wearables and other technology to track safety compliance and incident trends, and rewarding employees for outstanding safety performance with individual and team bonuses.

-

Offer Competitive Benefits and Work Perks

In a tight labor market, manufacturers need to offer their employees more than competitive base pay if they want to hang on to top talent. Providing a well-rounded benefits package sends the message that the employer values its workforce and is willing to invest in its people. To stand out among rivals, companies should offer affordable health insurance, generous paid time off, matching retirement savings plans, overtime pay, and additional pay for working nonstandard hours, such as the overnight shift.

Beyond traditional benefits, modern manufacturing companies are increasingly providing employee perks that support a healthy work-life balance, including flexible schedules, remote work for eligible positions, college tuition reimbursement, student loan payments, childcare assistance, commuter shuttle buses, and onsite fitness centers. Also, simple gestures, such as free coffee and food during meetings, can go a long way toward making workers feel appreciated.

-

Provide Clear Avenues for Career Growth

Manufacturers should prioritize clear growth opportunities for their employees. For instance, companies might provide upskilling through mentorships and structured training programs that prepare entry-level employees to move up the ladder. Also, manufacturers should be transparent about their job openings, posting them widely and providing early access to staff to encourage people to apply for internal promotions to higher-level positions. Managers can also turn performance reviews into opportunities to ask employees about how they’d like to grow beyond their current roles while providing personalized recommendations to help workers achieve their career goals—an endeavor that helps prevent people from feeling stuck in a stale job or, worse, from looking for greener pastures elsewhere.

-

Create Employee Development Programs

Beyond discussing an employee’s career goals, manufacturers can go a step further by creating structured development programs for technical training, tuition reimbursement, and on-the-job cross-training that teaches new competencies. Effective employee development in manufacturing might include providing certification training for handling new machinery, apprenticeships for learning on the job, or leadership boot camps, all tailored to fill both current and future skills gaps.

Manufacturers looking to implement successful development programs should start by assessing employees’ aspirations through surveys and performance reviews, then design customized training that aligns with the business’s strategies. Companies can also leverage technology, such as skills mapping and management platforms, to gauge employees’ competencies and create visual skills matrices to track individual progress on projects and match employees with the right roles and projects, with the goal of further developing their skills.

-

Reward Employees for Company Success

When a manufacturer shares its wins with its employees, it sends the message that it values their contributions. Rewarding employees for company success fosters a sense of ownership in the work, allowing individuals to align their personal work goals with organizational outcomes. These rewards also show people that their hard work has impacted the company’s prosperity and that everyone gets to share in the fruits of their labor. Manufacturers might consider the following approaches to rewarding employees for company success:

- Profit-sharing plans allow employees to receive a portion of company profits.

- Gainsharing initiatives tie bonuses to departmental or team performance wins, such as delivering orders in advance of deadlines or reducing waste, which encourages collaboration and greater collective accountability.

- Extra paid time off or greater schedule flexibility is an excellent reward for meeting or exceeding team goals.

- Gifting items or experiences for the whole team, such as gift cards, spa treatments, or dinner outings, promote team bonding and reinforce the idea that when the company succeeds, so do its workers.

- Career development incentives reward high performers with access to new training, certification, and promotion opportunities.

-

Be Up Front About Expectations

Spelling out job expectations from the get-go is important to avoid a disconnect between what people assume a job will be like and what the day-to-day work actually entails. When employees understand exactly what’s expected of them, they start the job feeling prepared and are more confident in delivering on those expectations. Clear expectations also help build trust between employers and employees.

To reduce ambiguity and avoid unrealistic expectations, manufacturers should be transparent in job ads and during candidate interviews regarding responsibilities, physical demands, pace, and advancement opportunities for prolific staff members. In addition, during onboarding, managers should allow new workers to shadow veteran employees to clarify production targets and quality standards, helping new hires learn the ropes quickly. Managers should also conduct frequent check-ins with new employees, particularly during the first few weeks, to answer questions, offer feedback on their initial work, and provide support for any challenges workers may encounter. Putting expectations in writing—through emails, training materials, employee handbooks, and other documents—can help prevent misunderstandings and reinforce expectations.

-

Modernize Your Technology Suite

Outdated systems and antiquated machinery that breaks down can ratchet up frustration, inefficiency, and even safety hazards for manufacturing employees, all of which contribute to decreased job satisfaction. Employees would much rather work for a manufacturer that employs a modern technology suite that enables an easier, more comfortable job.

To update their technology suites, manufacturers should start by assessing pain points and slowdowns in the production process to determine which new tools will speed up and simplify workflows. For example, deploying AI-powered quality controls can automate the detection of defects and reduce manual inspections. Integrating Industrial Internet of Things systems enables predictive maintenance and remote monitoring, reducing both physical strain on workers and downtime on the factory floor. Wearable sensors, meanwhile, can monitor ergonomics and fatigue to prevent injury, while signaling to employees that their well-being matters to their employer. And upgrading to cloud-based ERP systems can streamline communication among departments and eliminate time-consuming manual tasks.

Enhance the Employee Experience With SuitePeople by NetSuite

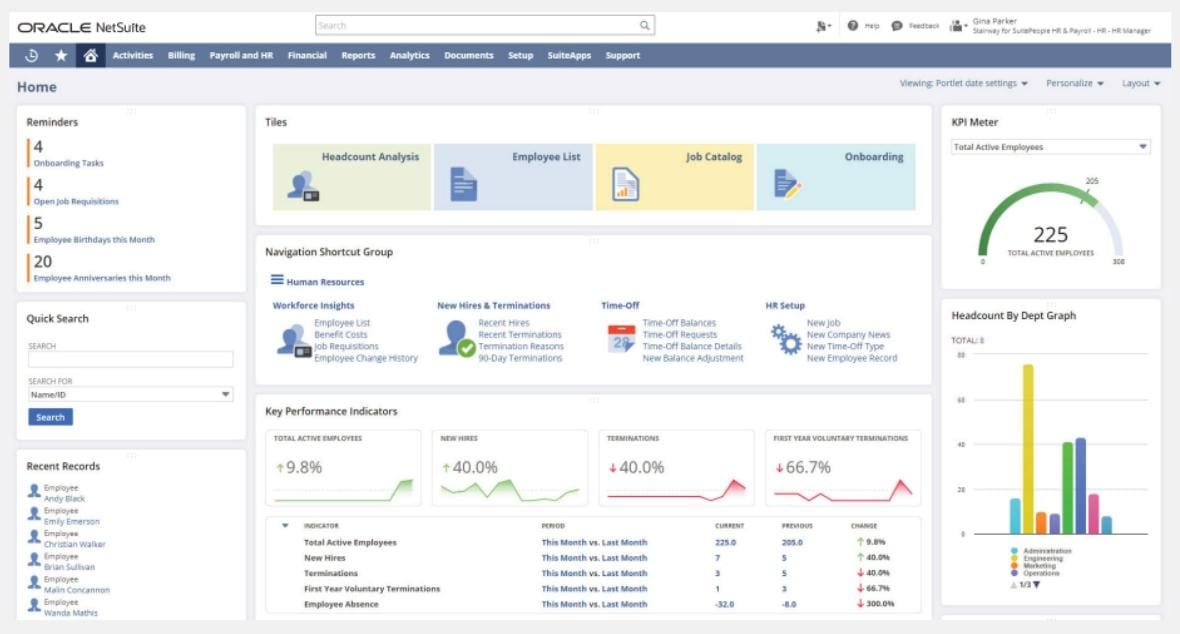

At a time when manufacturers are struggling to retain talent, the right technology can help companies seamlessly manage their people and human resources processes quickly and accurately, while providing the kind of positive experience for the workforce that minimizes turnover. NetSuite’s SuitePeople human resource management system allows manufacturers to quickly handle payroll and other HR processes, improve data accuracy, and assist employees with a variety of tasks.

For instance, SuitePeople provides employees and managers with self-service capabilities to update addresses, add bank accounts, view time off balances, and access copies of paychecks. A goal-setting feature allows employers to review and reward the achievements of staff. And SuitePeople Kudos gives employees opportunities to publicly recognize their colleagues for their hard work. Manufacturers can also use this data to create engaging performance reviews, as well as identify talented employees who might be strong candidates for promotion when higher-level positions become available. In addition, the system supplies workers with onboarding checklists to help new hires feel welcome and ease the stress of learning their roles.

NetSuite SuitePeople

With many manufacturers reporting turnover rates of 10% or more, business leaders say attracting and retaining talent is a primary business challenge. The good news is that turnover doesn’t need to be inevitable. Understanding what drives employees to leave—and inspires them to stay—can help manufacturers build a more stable and engaged workforce. From prioritizing workplace safety and recognizing workers’ achievements to offering competitive benefits and upgrading technology to streamline workflows, manufacturers can draw on numerous strategies to improve employee satisfaction—and increase retention.

Employee Retention in Manufacturing FAQs

What is a good employee retention rate in manufacturing?

A strong employee retention rate in manufacturing is typically considered anything above 90%, especially for hourly roles that tend to see higher turnover. Best-in-class manufacturers are often able to achieve a higher retention rate through strategies such as offering competitive pay, making safety improvements, creating career advancement programs, and upgrading technology to improve the day-to-day work of frontline employees.

How can managers retain staff in a culture of high turnover?

To improve retention when turnover is high, managers should start by assessing the reasons why employees are leaving. They should then focus on developing initiatives to reduce turnover, such as creating a welcoming atmosphere, providing adequate training, and building a healthy workplace culture where employees feel valued and heard. Managers can take additional steps to retain staff by offering career development opportunities, recognizing and rewarding people’s contributions on the job, offering competitive benefits, providing a clear path for career growth, and modernizing the company’s tech suite to minimize tedious tasks and improve productivity.

How do you motivate manufacturing employees?

To motivate manufacturing employees, start by recognizing their accomplishments through public praise and small rewards, such as gift cards or team lunches. It’s also important to invest in upskilling and provide growth opportunities through cross-training, certification and mentorship programs, and leadership boot camps that demonstrate a clear path for promotion within the company. Offering performance-based incentives, such as profit-sharing and bonuses tied to meeting team goals, can help employees feel valued, engaged, and motivated to continue putting in their best effort.

How do you retain high-performing employees?

Publicly recognizing employees for a job well done can go a long way toward making employees feel appreciated for the time and effort they put into their work. Plus, rewarding employees with extra days off, more flexible scheduling, and bonuses shows that the employer cares about keeping staff happy. Extra benefits, including onsite childcare, fitness centers, tuition assistance, and student loan reimbursement, can also help retain high-performing employees.