What is NetSuite Work Order Management?

NetSuite work order management capabilities add control and visibility when producing assembly items for stock or to fill orders. Bring efficiencies to your manufacturing processes by being able to easily define assembly items, build complex multi-level bill of materials, create work orders, record assembly builds, and backflush components with minimal effort.

Add visibility and control to the production process

Connecting Manufacturing and Financials

Link production processes to financial reports, inventory and outstanding orders, allowing you to see the impacts of manufacturing processes throughout the organization in real-time.

It would be impossible to continue to grow as we have without NetSuite. We have customer financial, production and manufacturing data all in one place.

Learn How ERP Can Streamline Your Business

Free Product Tour (opens in new tab)

NetSuite Work Order Management Benefits

NetSuite Work Order Management Features

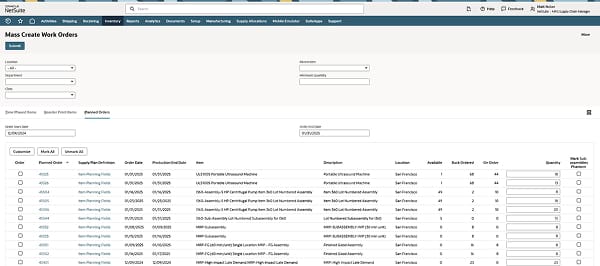

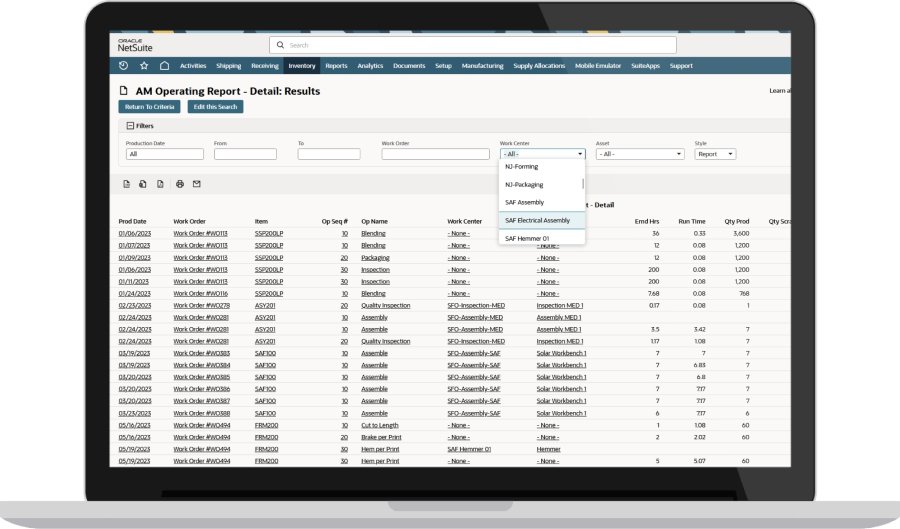

NetSuite work order management capabilities help control process workflows and increase operational visibility by organizing and tracking changes.

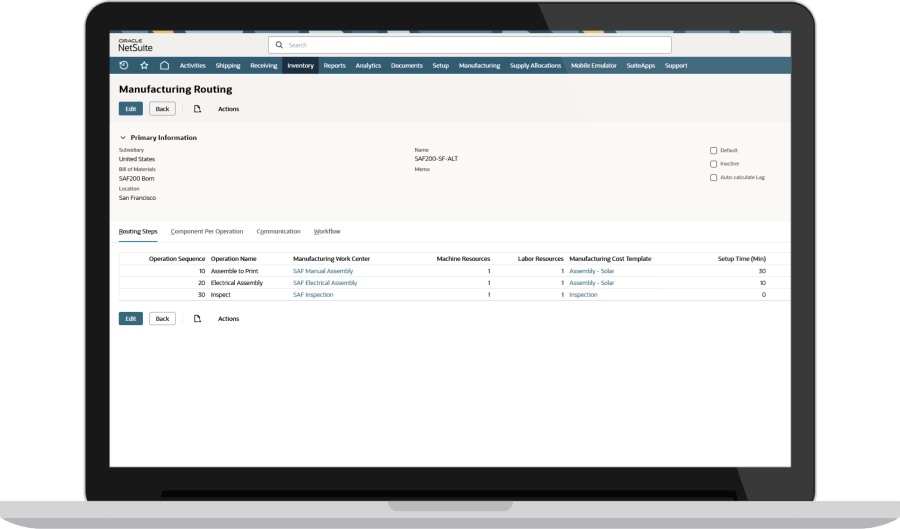

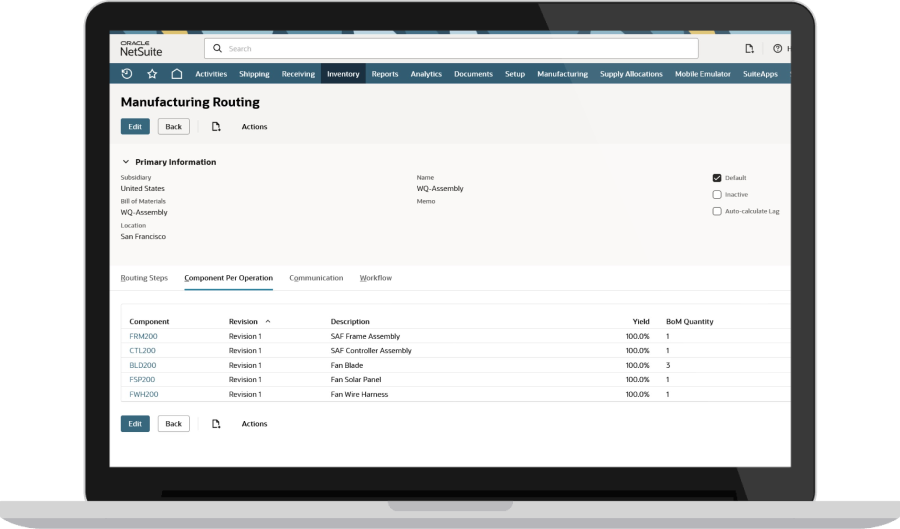

Discrete Manufacturing

NetSuite offers discrete manufacturers options for managing production processes, regardless of their size, complexity or business maturity. Work without work orders, backflush all materials upon completion, issue and track materials and labor as work-in-process costs, or define and track labor through a routing ticket system. Need flexible configuration options by location, configurable work order completion logic and enhanced data collection? NetSuite supports it all.

Batch Processing

With NetSuite work order management capabilities, every batch is individually processed and tracked. Combined with NetSuite’s native lot tracking functionality, that provides complete end-to-end traceability. Machines, employees, work centers and assets are scheduled and assigned to each individual batch, and NetSuite’s manufacturing execution systems and barcode and tablet interfaces ensure that all data is tracked and updated in real time. Batch processing functionality supports alternate assets, coproducts, and detailed work instructions for recipe/formulation management. Combined with FIFO material issuance for raw and bulk lot-controlled items as well as Batch Travelers with Batch Lot ID manufacturers benefit from full lot track traceability and enhanced material issuance control.

Shop Floor Controls

Easily prioritize, track and report against production orders and schedules, including evaluating current resource status, labor and machine use. Gather supporting information right from the floor, in real-time. Control how employees, materials, machines and production time are deployed, and using the tablet, provide instant feedback and visual warnings right to workstations. A work order traveler — a system-generated document — provides shop floor personnel with needed manufacturing specifications and travels with the job as it progresses through the shop.

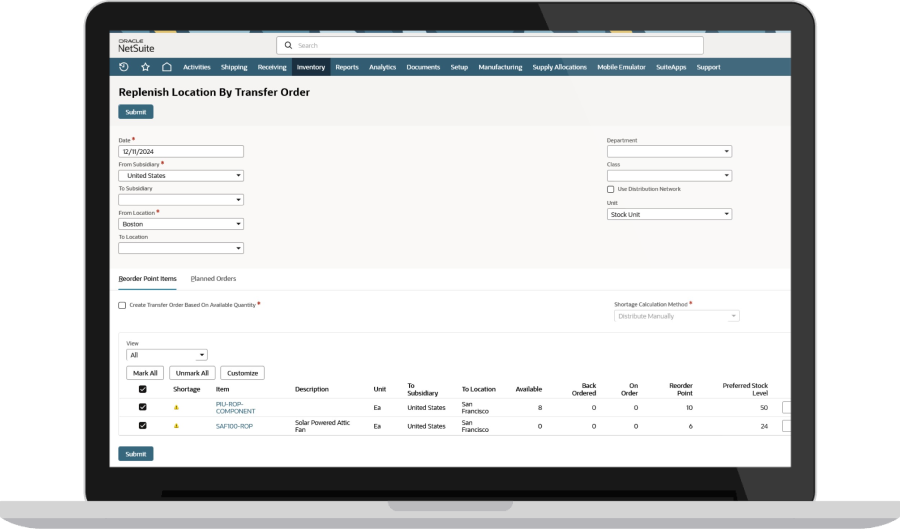

Transfer Order Management

If you store inventory across multiple locations, NetSuite’s transfer order management allows you to easily move items to the correct sites in preparation for assembly. Existing integrations with external warehouse management systems can leverage this insight to manage data about inventory movement between locations, and transfer orders can initialize item fulfillment and item receipt transactions.

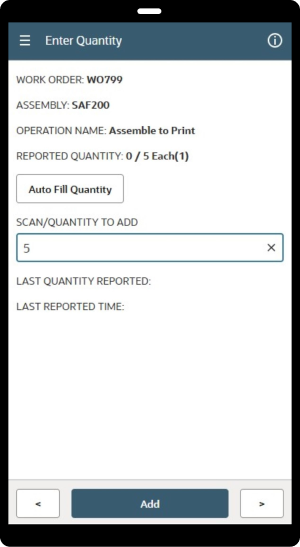

Manufacturing Mobile

The NetSuite Manufacturing Mobile SuiteApp enables production operators and managers the ability to complete warehouse and shop floor transactions directly from a mobile scanner. This increases efficiency, minimizes human error and delivers accurate data with real-time visibility.

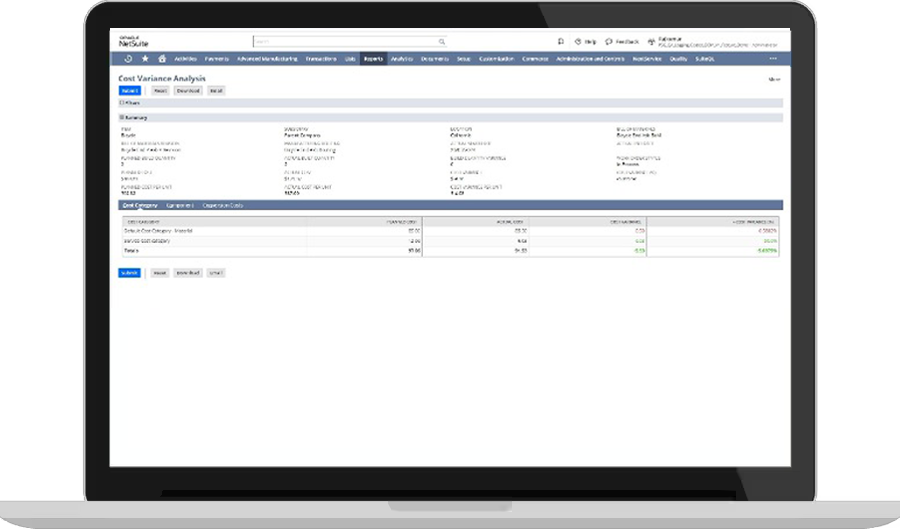

Cost Controls

Analyze work order costs by component, cost category and conversion costs using the NetSuite Cost Variance Analysis SuiteApp.

Inventory Usage

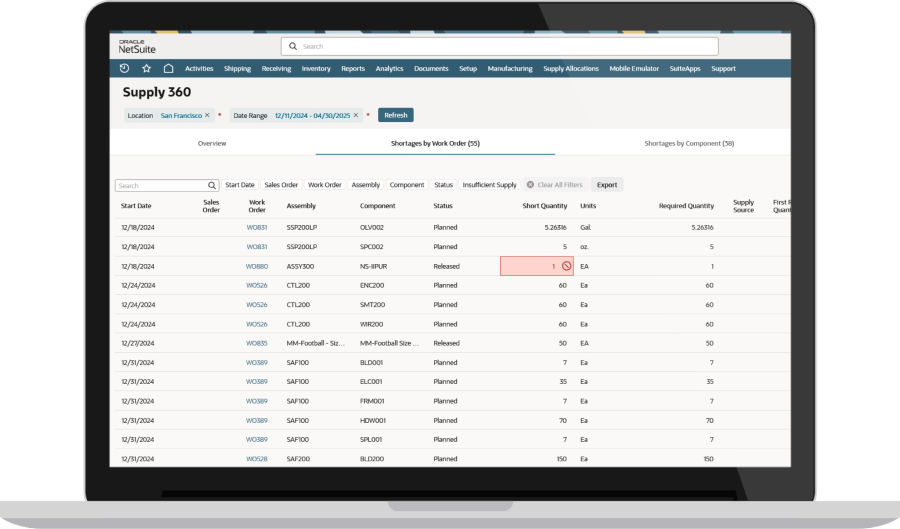

Review levels of component inventory for upcoming work orders by location and date and identify potential component shortages before they impact production with the NetSuite Supply 360 SuiteApp.

Understand what assemblies can be built using current inventory on hand using the NetSuite Available to Build SuiteApp.

Challenges NetSuite Work Order Management Solves

How Much Does NetSuite Work Order Management Cost?

Companies of every size, from pre-revenue startups to fast-growing businesses, have made the move to NetSuite. Looking for a better way to run your business but wondering about the cost?

Users subscribe to NetSuite for an annual license fee. Your license is made up of three main components: core platform, optional modules and the number of users. There is also a one-time implementation fee for initial setup. As your business grows, you can easily activate new modules and add users – that’s the beauty of cloud software.

NetSuite Work Orders and Assemblies is an add-on module as well as part of the WIPs and Routings and Advanced Manufacturing modules.

Contact NetSuite Now(opens in new tab)Resources

Data Sheets

Access specifications, features and benefits of NetSuite work order management capabilities.

Customer Stories

Spark ideas with success stories from NetSuite customers.

Product Demos

See NetSuite work order management capabilities in action.

Essential Learning

Discover best practices and learn more about work order management from beginner to advanced levels.