Delivery lead time is the time between when an order is placed and when it is delivered. If a business knows how long a delivery lead time will be, it can use that information — and its knowledge of when it need to receive something — to figure out when to place an order. All the processes that enable an order to be delivered affect delivery lead time, including design work, production, quality control, packaging and shipping.

What Is Delivery Lead Time?

Delivery lead time measures the period between when an order is placed and when it’s delivered. It is important in supply chain management and can be a particularly useful metric in managing inventory and logistics.

Delivery lead times are relevant in three supply chain situations. First, they provide a sense of the timing of inbound orders — that is, how long it will take for purchases from a supplier to arrive. Understanding the delivery lead time from upstream suppliers is essential for inventory planning and supply chain management.

The second important type of delivery lead time relates to outbound or downstream deliveries — or how long it takes to get an order to a customer. Not every business has customers for whom delivery lead times will influence decisions, but for those who do, this type of delivery lead time is critical.

Internal delivery lead times are a third consideration. Not every supply chain transaction occurs with an external party. Delivery lead times are just as important to businesses that own and operate the different pieces of the supply chain — for instance, the factory as well as the warehouse.

Design and production processes aren’t the only factors that affect delivery lead times; other factors include suppliers’ available capacity, their geographic location and logistical constraints, and the volume of the order. Sometimes price can be another factor in a delivery lead time, in the case of a one-time rush job for a customer who is willing to pay extra, for instance.

Delivery lead time vs. lead time: “Lead time” is a more general term than “delivery lead time”. Lead time can refer to the time between initiation and completion of just about anything — for example, the lead time for ordering gifts so they’re available for a holiday, securing tickets for a Broadway show or making sure one has a turkey for Thanksgiving. All delivery lead times are lead times, but not all lead times are delivery lead times. Nonetheless, the terms are often used interchangeably.

Key Takeaways

- Delivery lead time is the period between when an order is placed and when that order is delivered.

- Delivery lead time tells a company how far in advance it needs to place an order for the delivery to arrive on time. It is one of the most important metrics for managing supply chains and inventory.

- Lower delivery lead times are usually better, especially with perishable inventory, though some techniques for reducing lead times come with trade-offs.

- Delivery lead times are mostly discussed in the context of when a business needs to place its order with a supplier, but they also apply to how quickly customer orders can be fulfilled and how quickly a business can move materials and products around in its own internal supply chain.

Why Is Delivery Lead Time Important?

Knowing the delivery lead time is a crucial part of inventory management, as there are costs and risks associated with having too little or too much inventory on hand. Delivery lead times become even more important with perishable goods, partly because of the risk that raw materials could spoil, rendering inventory obsolete. And even if a shipment delay doesn’t render inventory worthless, the inventory’s useful life could decline in transit. Time spent in transit — a component of delivery lead time — can mean a shorter shelf life.

If orders rise to a level that can’t be fulfilled, customers may lose patience, complain or perhaps take their business elsewhere. Having a clear understanding of delivery lead times and open communication channels can lead to providing accurate answers and to more satisfied customers.

How Is Delivery Lead Time Calculated?

The simplest way to calculate delivery lead time for a finished order is to compare when it was delivered against when it was ordered. To estimate the delivery lead time of a future order, look at similar past orders and assume that the average elapsed time will be close to what will transpire with the upcoming order.

Another way to determine the delivery lead time for a future order is to identify all the steps involved in the order’s successful completion, attach times to those steps and then add them together. This approach — called the addition method and discussed in detail, below — is especially useful when something about operations or logistics is different enough that the past experience becomes unreliable as a model.

How to Calculate Delivery Lead Time

The math of delivery lead times isn’t complicated. Below are the two main ways to do it and the calculations for each.

-

Subtraction or empirical method. The subtraction method allows precise calculation of delivery lead time for a specific instance. It’s top-down and backward-looking, and relies on two data points: when the order was placed and when it was delivered. Here’s the formula:

Delivery lead time = (when order was received) - (when order was placed)

First, decide what units of time to express the answer, then input data for the two variables accordingly. For business processes where time of day isn’t relevant, days may be used as the unit of time, thus avoiding false precision and unnecessary noise. For instance, if a supplier’s trucks go out at 8 a.m. each morning, it doesn’t matter whether an order is placed at 8:05 a.m. or 4:30 p.m. In such a case, the delivery lead time would be expressed in days — “1 day,” “3 days,” “5 days” — not hours. For other types of orders, days might not be a granular enough measure. Some office supply delivery services measure their delivery lead times in hours and minutes, all but guaranteeing orders will be fulfilled on the same day they’re placed. If a business is hiring a construction company to build its new headquarters, on the other hand, it will likely measure that delivery lead time in months.

Of course, delivery lead times can change between orders. If a customer is ordering substantially more of something than it has in the past, or if the supplier’s production capacity is already stretched when the order comes in, the delivery lead time could well be longer.

-

Addition or component method. This second method is more bottom-up and gets an answer by assembling components. It can be built from actual data from a single transaction or from averages across multiple transactions. It can even be a theoretical calculation using assumptions as inputs.

To employ this approach, estimate the time needed for each sequential process that moves the transaction from the order-placed stage to the order-delivered stage. Not every business, product or transaction will have the same process list, so it’ll need to customize it. Design is a common input and so is processing or cycle time, which is the period required for a worker to produce one unit of a product. Other common inputs are production, quality control, order packing, packaging, assembly and delivery logistics.

To successfully use the addition method, make sure that, first, all of the important components are factored in. If unfamiliar with the processes, seek out more information. Missing an important step could result in an overly optimistic estimate of the delivery lead time, leaving a business without inventory when it needs it. When determining delivery lead time from a supplier, the business won’t necessarily have access to all the pertinent information. In that case, it may need to ask the supplier directly or use the subtraction method with recent data, if it has worked with the supplier in the past.

The second thing that must be done is subtract the time for processes that can be performed concurrently. Suppose the business is calculating the delivery lead time on an order of custom water bottles for a corporate event. The three main steps might be: making the water bottles, getting the design properly programmed into the machine that prints logos on the water bottles and printing the logos on the bottles. Suppose it takes two days to make the water bottles and one day each for the other two steps. But if the printing machine can be programmed while the water bottles are being manufactured by a different machine, steps one and two can be done concurrently. In that case the business would only need three days, plus shipping and handling time, not four.

Said another way, using the addition method requires not only an understanding of the steps but also the dependencies — the order in which things have to happen and whether any steps can happen simultaneously.

The addition formula is usually written like this:

Delivery lead time = (sum of times to complete each step) - (total time saved from overlapping work)

To use the formula for a particular calculation, make a list of the components that are most important to the situation and enter realistic numbers.

The steps in the addition method are as follows:

- Identify all activities that must be completed between order receipt and order delivery. Leaving anything out will result in underestimates of delivery lead times.

- Estimate how long each of the activities will take. The timing of the order may matter here. The estimated lead time for an order placed around Christmas will likely be different than for an order placed in June.

- Identify which order-filling activities will happen concurrently, and how much time will be spent on those overlaps. Missing something here will result in overestimates of delivery lead times.

- Add up time estimates and subtract time spent on overlapping activities. The resulting number is the delivery lead time.

Delivery Lead Time Examples

The subtraction method works well when working with a supplier you know well, and the supplier has no obvious capacity constraints. We’ll use the example of an electronics retailer to illustrate it.

This retailer is expecting an influx of business from a conference that a nearby college campus is hosting. Specifically, the retailer expects to sell a lot of clickers that advance PowerPoint presentations remotely. The longer the retailer waits to place the clicker order with its supplier, the more information the retailer will have about the number of conference attendees. But the retailer also does not want to wait too long to order and risk not having the needed supply of clickers when the visiting academics are in town.

The retailer looks at its records of orders and deliveries. The last order it placed for slide clickers was on October 7, and it was delivered October 12; that’s five days. To be safe, the retailer performs the same calculation on the last four deliveries and gets five days, six days, five days and four days. The retailer reaches out to its supplier, with whom it has a good relationship, and asks if the slide clickers are readily available, or whether there are any delays or back-orders that could affect delivery lead times. After being assured that there’s no looming problem, the retailer decides to place the order seven days in advance. That is as long as it has taken at any other point in recent months, plus one additional day of buffer time.

To illustrate the utility of the second method — addition — we’ll use another example of a preexisting customer-vendor relationship, but this time involving an unusually large order. The vendor in this case is a furniture maker. It has been asked by a large client how long it would take to outfit each of 400 offices in the client’s new headquarters with a desk. The furniture maker realizes that its past deliveries to this customer won’t be very instructive, because of both the size of the delivery and the vendor’s new location. To calculate the delivery lead time, the vendor’s manufacturing director and the sales manager for the account get together in a conference room and start putting some numbers on a whiteboard.

It will take them two days to gather all the materials and components they need, before which no work can start. At peak capacity, the furniture maker’s production facilities can make up to 600 desks per eight-hour shift, so they should be able to produce the whole order in a day, as long as there aren’t more than 200 other desks being made that day. The hard part will be getting the desks to the new building and setting them up in each office — basically, fulfilling an installation requirement that is part of the contract. The company has limited trucking capacity, so it will take three days to get every desk to the customer site and another four days — given available personnel — to set up every desk. But desks can start to be installed after the first day of deliveries is completed. That means there are two days of overlap in the previous calculation of three days to get every desk on-site and the four days to set up every desk.

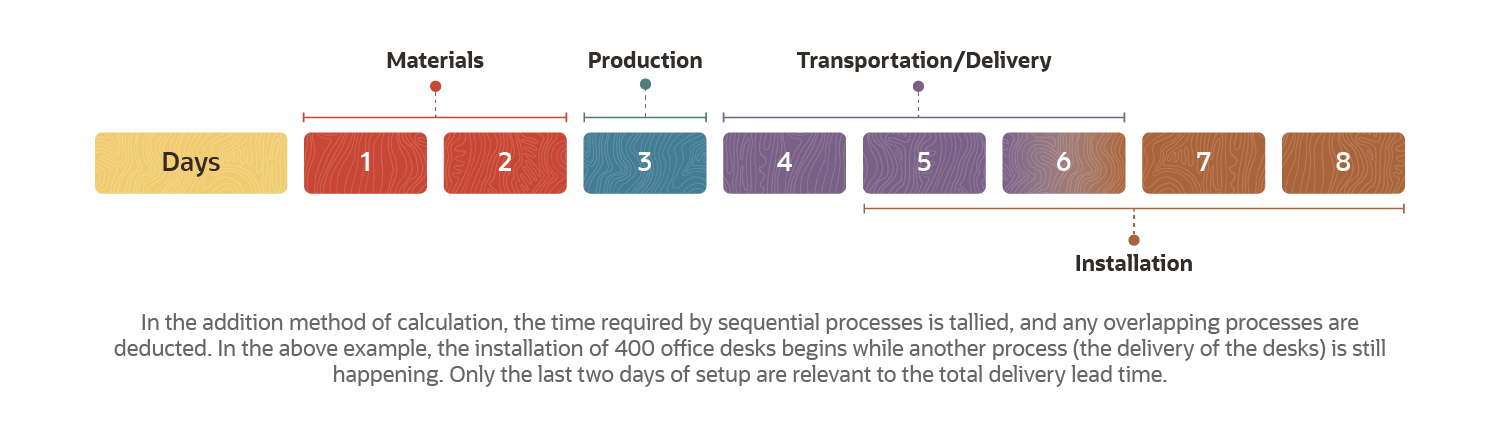

The delivery lead time for this order would be calculated in this way: 2 days (materials) + 1 day (production) + 3 days (transportation) + 4 days (setup) - 2 days (overlap) = 8 days. The project plan would look like this:

Since the addition method is forward-looking, the accuracy of time estimates is crucial; so is not forgetting any steps. The time unit can be months, days, hours or even seconds, depending on the situation.

How to Reduce Delivery Lead Time

Longer delivery lead times can increase cost and, in the case of perishable inventory, can cause some or all of the value of a delivery to be lost. Longer delivery times render businesses less responsive and, therefore, less competitive. By contrast, shorter delivery times are generally associated with higher customer satisfaction levels. Theoretically at least, they should also lead to an ability to fulfill more orders and sustain higher sales volumes over the course of a year.

The advantage of shortening delivery lead times is clear, but how does a company do it? Here are some strategies that have proven effective.

-

Break large orders into smaller ones. Larger orders take longer to fulfill. There’s more to make, more to ship and more complexity to manage. And if the supplier has capacity constraints that a large order can bump up against, such as a limited number of trucks or a small factory, large orders can take extra time. A business customer that places smaller, more frequent orders — or a supplier that encourages them — can get the benefits of reduced delivery lead times.

Of course, smaller orders are a double-edged sword. If they are too small, a business may lose out on economies of scale and volume discounts. A half-full truck uses the same vehicle and driver hours as a completely full truck. To avoid the potential side effects of reducing order size, know the tradeoffs and move in a direction that makes the most all-around economic sense.

-

Take advantage of automation. Manual processes take time and introduce errors, which are often time-consuming to fix. A lot of supply chain processes can be handled, in full or in part, by technology. Software can help track inventory, calculate key performance indicators and pinpoint optimal reorder points. Smart hardware — such as systems that use computer vision and cameras to monitor progress and count inventory levels — can add even more capabilities.

-

Use labor more efficiently. Multitasking can save time. By working on tasks concurrently, instead of in sequence, delivery lead times can be significantly reduced. If employees are often sitting around waiting on other people, it could signal the need for process improvements. If the only reason that tasks are being done sequentially is that there aren’t enough employees, bringing in help could provide a boost that more than pays for the added labor costs.

-

Optimize and localize supply chains. There are plenty of books that focus on ways to optimize supply chains. A good first step, however, is to look at the longest distances that products and their inputs have to travel. Can four days be saved by finding a local supplier for a part or ingredient that is essentially a commodity? A month by cutting out a trans-Pacific cargo container? Going local may have a short-term cost, but it can also reduce delivery lead times materially. If a business’s goods are durable and its customers are patient, creating a more geographically concentrated supply chain may not be a priority. To other businesses, it can be the difference between success and failure.

-

Establish deeper relationships in the supply chain. Good relationships with supply chain counterparts can be a huge help in reducing delivery lead times, and especially in avoiding surprising or unexpected spikes in those lead times. Open communication can help a buyer understand the capabilities and constraints of a supplier, and help the supplier understand and prepare for the upcoming needs of a buyer. Whether supplying or buying, a good relationship lets you be proactive, rather than reactive.

In some cases, long term buyer/supplier relationships will include contractual incentives to keep delivery lead times low. These incentives can include rewards for excellent performance, such as financial bonuses or priority over other suppliers going forward. Contracts can also specify penalties for underperformance.

Optimize Delivery Lead Time With Software

To optimize delivery lead time, look into a software solution. Tracking inventory at different points in the supply chain; calculating key metrics in real time for every product, input and line of business; and integrating supply chain data with financial data and billing and payment processes are all herculean challenges for a human. But for a good software-based inventory management system, these tasks are merely part of the daily routine.

NetSuite Inventory Management can scale with a business and calculate key metrics, such as lead times, reorder points and safety stock levels. Good data management will free up time to focus on bigger improvements, while also providing informational inputs to identify where and what those improvements could be.

Conclusion

Delivery lead time is an important metric in supply chain management. Whether a business is buying, selling or moving goods and materials around within the company, it’s important to know how long a product takes to go through the pipeline from initial order to delivery. Good software can monitor results, establish consistency and even identify opportunities for improvement.

Delivery Lead Time FAQs

Is lead time the same as delivery time?

The two terms are often used interchangeably. “Lead time,” however, is a more general term. It refers to the time between the initiation and completion of a business process — pretty much any business process. The more specific “delivery lead time” refers to the time between an initial order and its delivery.

How is delivery lead time calculated?

Delivery lead time is usually calculated after the fact as the time between when an order was placed and when it was received. Delivery lead time can also be estimated by looking at the steps needed to complete an order and tallying how much time you expect each sequential step to take.

What is the lead time in purchasing?

The lead time in purchasing, sometimes called purchase order lead time (or POLT), is just another name for delivery lead time. POLT is often used when formal purchase orders are involved or in cases where a company is purchasing raw materials for production. Conceptually, however, there’s no difference between the two terms.