What makes customers place one product in their shopping carts and put another back on the shelf? In the eyes of the customer, the product that made it to the cart likely offered a higher perceived value than the one left behind. Every step of a business’s operation contributes to the value a product offers to customers, and each of those steps is part of the value chain.

By analyzing their value chain, businesses can determine where they might have an edge over their competition and where they may fall short. An analysis of the value chain can help businesses find any deficiencies in their operations, so they can save money and improve the quality of their products to gain the attention of customers. Ultimately, a business with an optimized value chain may create more superior products than its competitors at a lower cost, which can give its products the best chance of ending up in customers’ carts—and allow the company to reap higher profits.

What Is Value Chain Analysis?

Value chain analysis is a way to study every step in the process of creating and distributing goods or services—from the initial design of products to customer delivery. But unlike supply chain analysis, which often focuses on the business’s needs, value chain analysis is framed around what the product—and the customer—stands to gain from each step.

For example, an appliance company may be spending more money per unit during the manufacturing process than its competitor. Through value chain analysis, the business may decide to simplify its production process to cut costs. Or it may determine that its current process is worth the extra expense, since it’s producing a superior product that can be sold at a premium price and is allowing the company to earn higher profits than the competitor earns. Applying that level of analysis to the entire value chain provides businesses with opportunities at every stage of their operations, enabling them to distinguish themselves from the competition—either by differentiating their products or reducing their costs.

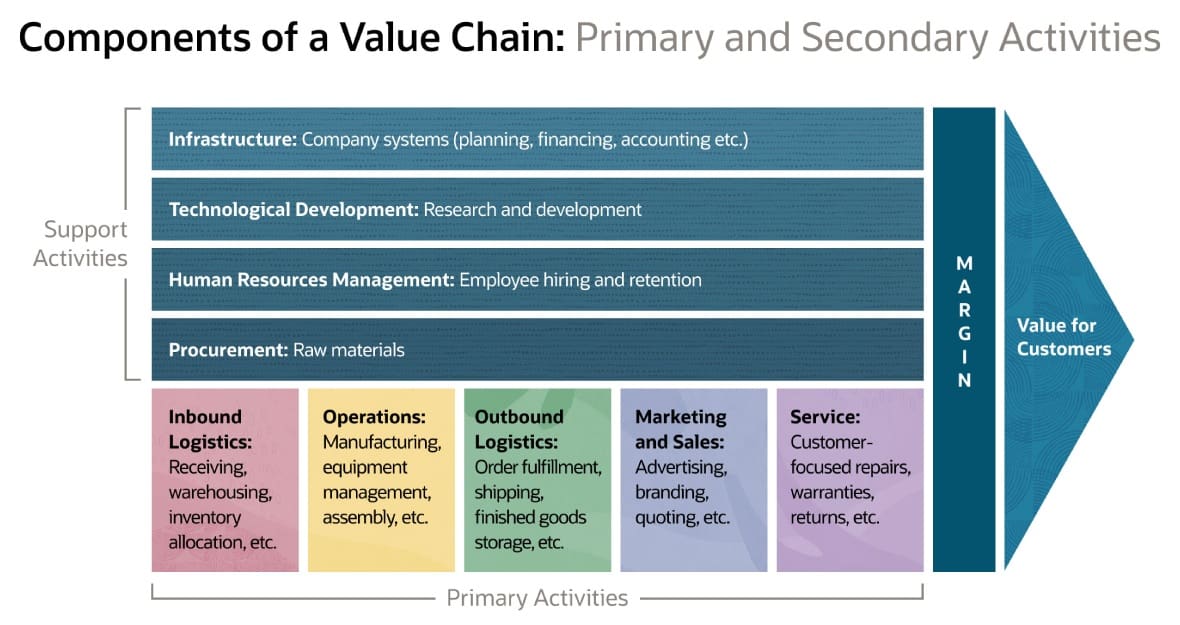

The is made up of two types of activities: primary and support. Primary activities are directly involved in the production, sale, and distribution of a good or service; they include manufacturing, order fulfillment, and marketing. Support activities increase the efficiency of primary activities through operations like evaluating a company’s infrastructure, conducting research and development, procuring raw materials, and managing employees. The illustration below shows that these steps all add value for customers.

Key Takeaways

- A company’s value chain includes every step involved in creating, delivering, and marketing a product or service.

- Value chain analysis focuses on developing a product or service that is better suited to the customer’s wants and needs than the products and services competing companies are offering.

- By analyzing the value chain, businesses can create advantages over their competitors, either by reducing their costs or differentiating their products.

Value Chain Analysis Explained

Harvard Business School professor Michael E. Porter coined the term “value chain” in his 1985 book, “Competitive Advantage: Creating and Sustaining Superior Performance,” and since then, analyzing the value chain has become an important way for businesses to improve their operations. Porter separated business operations into primary activities and support activities. Each activity can be analyzed and optimized to make sure value is efficiently being added and waste is being reduced. Businesses using value chain analysis can look at every activity and ask two questions: What value does this step in the process contribute to the final product? Can that value be accomplished more efficiently?

Value Chain Analysis Components

Examining each component of the value chain reveals opportunities for cutting waste and adding value that might otherwise go unnoticed. Even small adjustments in each step can significantly reduce redundancies, ease bottlenecks, and make process improvements that compound throughout the entire operation to deliver higher quality goods faster and more reliably. In his book, Porter segments the two main value categories—primary and support/secondary activities—into subcategories to help businesses better identify where they can find these adjustments to enhance both product quality and operational efficiency.

Primary Activities

Primary activities are directly involved in producing and selling products and are divided into five categories:

- Inbound logistics: Companies typically need to collect, store, and use raw materials to manufacture their products. Receiving, warehousing, inventory control, and storage of supplies are considered inbound logistics, which can be analyzed to find ways to cut costs.

- Operations: The processes that take raw materials and turn them into the finished product are known as operations in the value chain. Optimizing the manufacturing process, including the use of labor and machinery, can help businesses fulfill orders in less time and for less money.

- Outbound logistics: After a product is manufactured, it needs to be prepared for order fulfillment. Outbound logistics may include shipping products to retail locations, storing them for ecommerce fulfillment, and managing in-store inventory levels. Streamlining this step is important because delays between order placement and the delivery of products could negatively impact the company’s relationship with the customer.

- Marketing and sales: A product has no value to customers unless they are aware of it and can purchase it. Through marketing and sales, a business can show the value of its products to customers and make them available through in-store or website sales.

- Service: Even though final delivery of a product often represents the end of the value chain, some products include post-sale services, like returns, warranties, and maintenance. These services may add extra value for customers—and, in some cases, generate extra revenue for companies as well. Reverse logistics systems can be used to maintain the value of a product long after the customer has returned an item, often by repairing or recycling the product.

Secondary Activities

Secondary activities help increase the efficiency of primary activities and are divided into four categories:

- Company infrastructure: The company’s infrastructure refers to its administrative, management, financial, legal, and quality control mechanisms—the structures a business has in place to make key business decisions and manage its resources.

- Technology development: This support activity includes the implementation of technological advancements, such as process automation and machinery upgrades. Technology improvements at various stages, from designing to manufacturing products, often help to reduce costs and increase efficiency and productivity.

- Human resources management: Whether targeted at welcoming new hires, implementing updated training programs, or retaining long-term employees, effective human resources management is crucial. A productive and knowledgeable staff can address concerns among employees and ascertain that staff members are happy and productive.

- Procurement: Procurement covers the purchase of raw materials, machinery, office equipment, and office space. Proper procurement operations provide departments with the resources they need to complete their responsibilities.

Why Is Value Chain Analysis Important?

Value chain analysis helps businesses deliver the most valuable products and services at the least possible cost. Through value chain analysis, businesses can find ways to optimize their processes to keep customers satisfied, thereby maintaining customer loyalty and increasing the likelihood of repeat sales.

Value chain analysis often takes a two-pronged approach: first, finding places where costs can be trimmed, then identifying how products can be improved. If a business can create superior goods that customers are willing to purchase and reduce its costs, it can often gain a competitive advantage and greatly increase its profit margins.

How to Conduct a Value Chain Analysis

Value chain analysis can seem daunting because of its widespread scope. After all, an analysis looks at every step involved in creating and selling a product. But analysts can simplify the process by following these five steps:

- Identify primary and support activities: The first step in value chain analysis involves identifying relevant activities so decision-makers can make improvements. For example, an electronics manufacturer would classify assembling the components of a product and shipping its orders to customers as primary activities. Support activities would include training the sales team and upgrading the warehouse machinery as new technology becomes available. This helps analysts determine the improvements that will directly benefit customers and the ones that will streamline operations and reduce costs.

- List the value and cost of each activity: Once all activities are identified, analysts can dig into each step and look at the value it adds to the product, as well as the associated costs. The electronics company’s assembly process may be labor-intensive, requiring multiple highly skilled workers to make sure every device is assembled to exact specifications. But even if the process is costly, this high level of quality control may be crucial to producing reliable products for customers.

- Research competitors’ value chains and customer values: Through market research, a business can get a baseline for how a competitor’s value chain is structured. For example, that electronics company can research the competition to answer questions like: Is our assembly process costing more than a competitor’s? How does the quality of our product stack up against others on the market? Similarly, looking into customer-demand trends and data from customer surveys can answer questions like: What else would customers like to see from the products we offer?

- Identify links between activities: Each link in the value chain contributes to the final product. It is critical for analysts to look at how any proposed changes will affect the value chain, since improving one step may negatively impact another and could end up decreasing the overall value of a product. If the electronics company switches its raw materials to a cheaper alternative, for example, the assembly process may become more cumbersome and slow down production.

- Identify and implement improvements to create advantages: Once a business has a clear view of its entire process and how it compares with competitors’ processes, analysts can find areas for improvement. These fixes can be simple and small, such as a tweak in the manufacturing process to shave a few seconds from each product’s assembly. Or, the changes may involve major restructuring, such as abandoning entire product lines. No matter the size of the improvement, it should aim for the same goal: getting ahead of the competition by creating a cost advantage or by differentiating products. In the example of the electronics company, decision-makers may have decided to keep its high-quality raw materials but make some changes to the assembly process to save time and reduce labor costs.

Cost Advantage vs. Differentiation Advantage

Earning and maintaining a customer’s attention in today’s market can be challenging. Through value chain analysis, businesses strive to both attract new customers and retain existing ones. The value chain can help a company achieve these goals in two main ways: by creating a cost advantage or a differentiation advantage.

Cost Advantage

Cost advantages are created by reducing costs in business operations where possible. When reducing costs, it is important to recognize any qualitative value that could be lost through cost-cutting measures, like purchasing cheaper raw materials or implementing shortcuts in the manufacturing processes. For example, if a shampoo company decides to cut costs by replacing an expensive ingredient with a cheaper substitute, would it lose customers to a competitor?

Differentiation Advantage

Differentiation advantages are created by enticing customers with a different or superior product from those sold by competitors. In fact, these superior goods may be sold at higher prices than similar goods, but customers may believe the higher-quality goods are worth those premium prices. Many businesses also offer post-sale services to justify higher prices on goods, such as warranties or repair contracts. If a customer is choosing between two similar washing machines, for example, the person may pick the one with a longer warranty, even if it comes with a higher price tag.

Cost Advantage vs. Differentiation Advantage

| Cost Advantage | Differentiation Advantage | |

|---|---|---|

| Goal: | Reduce production and distribution costs without losing value. | Provide unique products or products superior to the competition. |

| How: | Find cost-cutting opportunities at one or multiple steps of the value chain. | Find steps in the value chain that cannot be easily replicated by competitors, either through expertise or new techniques. |

| Financial impact: | Lower costs can increase profit margins. | Unique features can increase customer demand, or premium goods can be sold at premium prices. |

| 🡇 | 🡇 | |

|

Higher Value for Customers Higher Profits for Businesses |

||

Benefits of Value Chain Analysis

The primary goal of value chain analysis is to generate more profits for a company by reducing costs and differentiating the business and its products. This is often accomplished by finding specific areas to improve upon, both through identifying inefficient areas that need restructuring and pinpointing successful areas to invest in further. Value chain analysis can create additional benefits for an organization, including:

- Better relationships with vendors: When a business fully understands the ins and outs of its value chain, it can streamline its ordering process with vendors. By optimizing raw material orders and making quick payments, a business can keep communication with vendors smooth for both parties. Better vendor relationships can lead to quicker fulfillment or more favorable terms, such as discounts on supplies.

- Shorter turnaround times: When customers place an order, they expect it to be processed quickly. Without a comprehensive understanding of the value chain—including any delays related to the supply chain—businesses may leave customers guessing about when their orders will be shipped. Dissatisfied customers are less likely to return and may even cancel their orders if a competitor can deliver the goods more quickly.

- Better inventory allocation: A business may have an efficient manufacturing process, but without proper allocation, produced goods either may not be readily available to meet customer demand or can accrue high carrying costs while awaiting delivery to retail stores, distributors, and customers. A value chain analysis can lead to improvements in managing inventory, which can reduce costs and increase customer demand.

- Standardized processes: As companies expand, communication can break down between departments. Miscommunication between teams involved in a sale—like a sales team processing an order without notifying the warehouse responsible for fulfilling it—can lead to costly delays and incorrect orders. By looking at the value chain as a whole, managers can make sure the entire organization is adhering to the same standards and keeping production running smoothly from one stage in the process to the next.

When Should Your Business Use a Value Chain Analysis?

While value chain analysis can almost always help businesses improve some aspects of their operations, it often delivers the most impact during transition periods or when targeted to overcome unique business challenges. When facing competitive pressures, compounding operational inefficiencies, or major strategic shifts, companies should aim their value chain analysis at specific steps that may house hidden opportunities. They should also take special care to proactively address any potential upstream or downstream pitfalls before making significant changes—for example, an improved assembly process creating a bottleneck in the shipping department from increased flow. Here are five key scenarios where value chain analysis proves particularly valuable:

- Increasing efficiency: When input costs rise and/or profit margins shrink, businesses can use value chain analysis to compare specific activities’ costs to the value they create and identify areas to target or eliminate based on which processes are underutilizing resources and earning lower returns on investment.

- Strategic planning: Assessing the value chain during annual planning or business model adjustments can provide a data-driven look into which activities would most likely benefit from additional investment and which should be restructured, reduced, or outsourced.

- Competitive benchmarking: If a company’s market share decreases or their competitors start pulling ahead, comparing its value chain with industry leaders can reveal specific operational gaps they can address to add new features or reduce prices to stand out.

- Mergers and acquisitions: Mapping and evaluating another company’s value chain before integrating can expose operational redundancies and compatibility issues, as well as potential improvement ideas the business can implement into its own existing operations.

- Adapting to market changes: When customer preferences shift or new technologies emerge, value chain analysis helps prioritize which processes to modernize to best serve future customers and maintain market relevance.

How to Improve the Value Chain

Improvements to the value chain don’t follow a one-size-fits-all approach; they must be aligned to the specifics of a business. But once identified through value chain analysis, managers can use these useful tips to continually monitor and fine-tune their operations—and make sure customers see the improvements, too:

- Identify and analyze the steps of the value chain: Value chain analysis may allow decision-makers to increase the value of a product by finding areas to reduce costs and/or improve the product. These improvements can come from anywhere in the value chain, from streamlining the steps in the research and development process to identifying new shipping methods to transport goods more quickly and affordably to customers.

- Implement fixes and track progress: Once fixes have been identified, managers can start implementing them. But they should not just “set and forget” value chain improvements. New technology, new techniques, and changing customer demands can quickly turn a “perfect” value chain into one that needs improvement to stay competitive. Tracking data like sales and costs, and key performance indicators like productivity can help businesses make sure that they remain just as—if not more—competitive tomorrow as they are today.

- Inform customers of improvements: When a business wants to get the word out about its improvements, typically through marketing and sales, it is important to highlight a product’s new and improved elements. By making an explicit statement of a product’s benefits, called a value proposition, businesses can lure new customers and solidify existing customers’ loyalty.

- Maintain and update internal value propositions: Internally, businesses with a clear value proposition have a guiding principle that helps to rally everyone in the organization around the same goals. Internal value propositions ensure that future improvements remain consistent with a company’s values.

Value Chain Analysis Example

TBI, a technology services distributor, was looking to simplify its processes across the organization to increase efficiency. Through value chain analysis, TBI found that its multiparty value chain could be improved by implementing a new business platform. By deviating from the industry standard and using a unified system designed for both support and primary activities, such as running financials, customer relationship management, and commissioning, TBI was able to streamline its cash workflow and increase visibility across the company. These changes gave TBI’s services a differentiation advantage, providing selling partners with higher satisfaction ratings than the competition’s, boosting repeat business, and generating a double-digit revenue increase.

By looking at the links in the value chain both individually and in their interactions with one another, TBI was able to make “the most successful technology move TBI has ever undertaken,” according to Jeff Newton, VP of enterprise sales and engineering at TBI.

Free Value Chain Analysis Template

Value chains vary not only by industry, but also among product lines within a company. For that reason, Porter’s value chain layout can be modified to fit almost any value chain a company uses. To help businesses get started, download our simple template here.(opens in a new tab) This template can help businesses identify primary and secondary activities and begin analyzing each area to determine the costs and the value of each step in the process, plus any potential improvements. This model can be replicated for each value chain in an organization’s business model.

Value Chain vs. Supply Chain

Value chains and supply chains are interconnected but distinct concepts that impact business strategies in different ways. Supply chains focus on the logistics networks that move materials, components, and products from vendors through the business to customers. Supply chain analysis views effectiveness through the eyes of the business, prioritizing cost reduction strategies and overall efficiency. Value chains, meanwhile, examine how each activity contributes to customer-perceived value, including qualitative benefits, like a more personalized customer experience or post-sales support options. Traditionally, value chain analysis goes beyond asking how to efficiently produce and deliver goods, instead focusing on how to maximize what customers gain from each step of the process.

Companies often integrate both perspectives into a single analysis to gain benefits that serve both businesses and their customers. A furniture manufacturer, for example, might use supply chain analysis to manage its suppliers and improve how it procures wood and metal components. At the same time, the manufacturer can conduct a value chain analysis to determine if ordering premium wood types will create enough additional customer value to justify higher prices. An approach that considers both helps businesses balance operational efficiency and cost management with strategic market positioning, often increasing margins in two ways—by simultaneously reducing production costs and commanding premium prices through enhanced customer experiences.

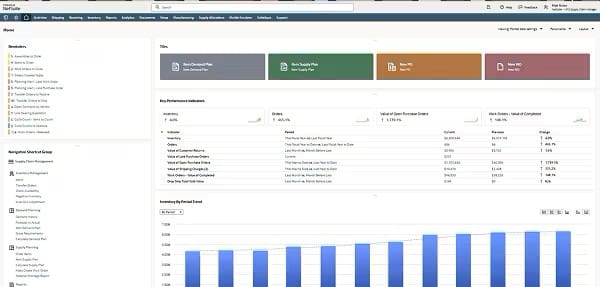

NetSuite’s Comprehensive ERP Improves Your Value Chain with Real-Time Data

Managing and mapping value chains manually can be unwieldy, especially for larger companies offering several products and services. NetSuite Supply Chain Management scales with businesses to provide insights into a variety of areas throughout the value chain that may need improvement.

From procurement of raw materials through product delivery, each link in the value chain can be monitored and managed to make sure value is effectively added, costs are reduced, and waste is minimized. The resulting data can increase transparency related to the production and distribution of products and ultimately lead to more reliable order fulfillment.

NetSuite ERP is an all-in-one cloud solution that can effectively handle inventory allocation with real-time data and forecasting tools. The unified platform allows businesses to examine their operations as a whole and gives them confidence that the links in all the value chains in the organization are working together efficiently and effectively to produce the best possible products.

Track the Flow of Goods and Materials With NetSuite

Businesses have used value chain analysis since the 1980s to gain a competitive edge. By separating value chain activities into primary activities, which are directly involved in production and sales, and support activities that increase efficiency, businesses can find areas for improvement throughout their organizations. These improvements can reduce costs and increase value for customers, giving products a cost advantage, a differentiation advantage—or both. By showing customers the high value of their products, businesses can boost profits and increase customer satisfaction, creating a more sustainable customer base for long-term success.

Value Chain Analysis FAQs

What are value chain management and mapping?

Value chain management involves overseeing every step in the production of a good, based on how much value it provides relative to the costs accrued at each step. Managers use value chain mapping to list every step involved and analyze each one to find areas for improvement.

What is an example of a successful value chain?

2pure, a U.K.-based distributor, used value chain analysis to make improvements in its warehouse operations and sales departments. This led to a 95% increase in revenue without the need for any additional staff.

Why does value chain analysis matter?

Value chain analysis allows businesses to gain an edge over their competitors, either by creating a cost advantage by reducing costs or by developing a differentiation advantage by offering a different or superior product. Businesses with a competitive edge are more likely to increase sales.

What is value chain analysis with examples?

A company conducting a value chain analysis looks at each step involved in its operations and finds areas where it can increase the value for customers and reduce the costs for the business. TBI, a technology services distributor, used value chain analysis and decided to implement a new business platform. By using a unified system designed for both support and primary activities, TBI was able to streamline its cash workflow and increase visibility across the company. These changes gave TBI’s services a differentiation advantage, allowing the company to outshine its competition.

What are the five primary activities of a value chain?

The five primary activities of a value chain are inbound logistics, operations, outbound logistics, marketing and sales, and service. These activities are all directly involved in the production and sale of goods.

What are the four support components of the value chain?

The four support components of the value chain are infrastructure, technology development, human resources management, and procurement. These activities increase efficiency for primary activities and add value to products.

What are the steps in value chain analysis?

Value chain analysis includes five steps:

- Identify primary and support activities.

- List the value and cost of each activity.

- Research competitors’ value chains and customer values.

- Identify links between activities.

- Identify and implement improvements to create advantages.

Using these five steps, companies can find areas where they can reduce costs and increase the value of their products.