Warehouse operations are continually looking to reduce operational costs and increase throughput. A step that can’t be overlooked in pursuit of those goals is the picking process, because the longer it takes to fulfill an order, the less profitable that order is.

Batch picking is an order picking methodology that, when implemented correctly, improves picking efficiency by grouping multiple similar orders into one pick instruction.

What Is Batch Picking?

Batch picking, also called batching or multi-order picking, is an order picking method in which pickers simultaneously collect items for multiple orders. Batch picking is generally faster than other picking strategies — such as single order picking, in which pickers tackle one order at a time — because it reduces warehouse travel time. Pickers report walking as many as 10 miles a day to perform their jobs, but batch picking eliminates the need to repeatedly revisit the same picking location multiple times in a shift as they fulfill orders, cutting travel time significantly.

Batch vs. Wave Picking

In batch picking, a single picker picks a batch of orders at the same time. The goal is to create an optimal pick path that prevents pickers from visiting the same item location multiple times when fulfilling multiple orders.

In wave picking, warehouse managers schedule picking windows — or waves — throughout the day. The goal Order are sent to fulfillment based on what is in them so that like orders can be filled together; it’s like a step beyond batch picking.

Batch vs. Zone Picking

Zone picking is another popular way to increase order picking efficiency. In batch picking, a single picker usually will fulfill several orders in full. In zone picking, a single order is split among multiple pickers who pick different items within the order that are located in a similar area (or zone) in the warehouse. Each picker is assigned a zone in the warehouse and only picks SKUs from that zone. Once the picker collects the necessary SKUs from their batch, they might put it in a tote and pass it on to the next zone until the entire order is picked.

Like batch picking, zone picking can increase picking efficiency by reducing travel time. However, zone picking does not require orders to be grouped together. This makes zone picking a better option for businesses that do not regularly deal with similar orders. But depending on a warehouse’s picking needs, zone picking may be combined with other picking strategies, like wave picking, batch picking or both.

Batch Picking Explained

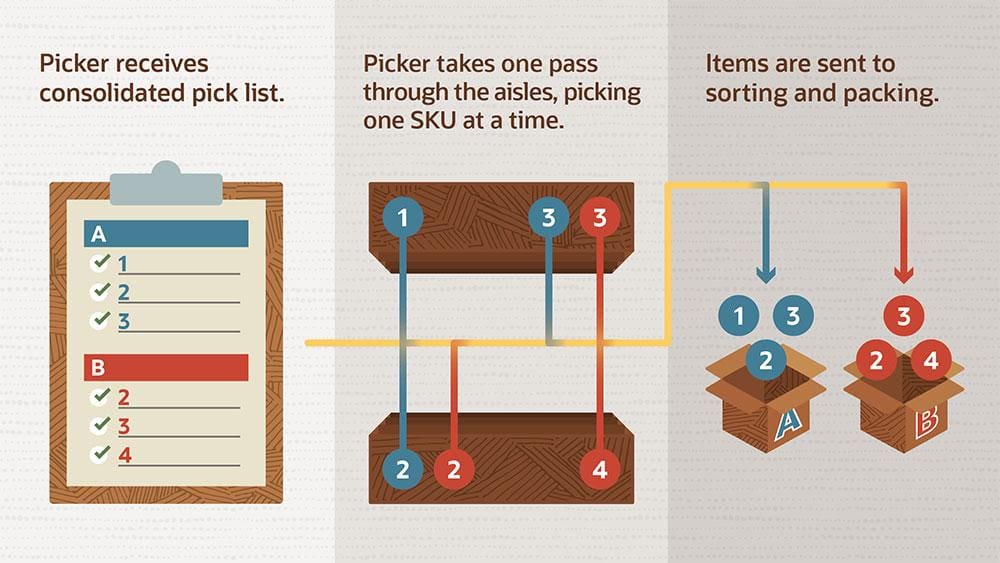

Batches usually consist of about eight to 20 similar orders that are consolidated into a single pick list. Orders that are batched together generally have several of the same items or even extremely similar pick paths. To establish optimal batch grouping and pick routes, it’s important to use a warehouse management system (WMS) and order management system (OMS). The WMS and OMS can analyze orders and your specific warehouse layout to create pick plans that minimize travel time, resulting in more time spent picking and less time spent walking.

Batch picking can be highly productive because workers are able to pick many SKUs for several orders in one trip, rather than making separate, repeated trips throughout the warehouse. Additionally, grouping picks means fewer people are moving through warehouse aisles at any one time. This leads to fewer bottlenecks, enabling workers to reach their destinations more quickly. Order need to then be sorted in the packing areas into their proper boxes.

How Does Batch Picking Work?

With a WMS or OMS in place to determine optimal batches and map picking routes, batch picking is a fairly straightforward process. Here’s how it works:

-

Create picking lists. A WMS or OMS usually generates a consolidated list with SKU(s), quantities and inventory storage locations. Picking lists can be created manually, but a WMS or OMS can automatically batch similar orders — such as those that comprise many of the same SKUs or require similar pick paths — to simplify picking operations and reduce travel time.

-

Assign and prepare pickers. Pickers receive their pick list and gather any equipment needed to complete each order, such as totes, carts and mobile scanners. Some operations might use additional technology like voice picking headsets, which direct the picker to the location of each item included in an order.

-

Pick the items. There are several ways pickers can collect items, usually dependent on the business’s needs. Some warehouses might have pickers push a cart that holds several small discrete totes for each order, while others may have workers pick directly into shipping boxes. Others may compile all like SKUs into a single bin that’s then sent to the packing team to be sorted and prepared for shipping. Regardless of the method, pickers follow their picking lists according to the plotted path, focusing on one SKU at a time. Workers often use mobile barcode scanners to track when they pick each item and its required quantity.

-

Pack and ship the orders. If orders were not sorted and packed into containers during the picking process, the picked items are sent to sorters who separate items into their respective orders. The orders are then appropriately packed and prepared for shipping. Meanwhile, the picker begins to pick their next batch.

Benefits of Batch Picking

Fast, accurate picking is important not only to simplify order fulfillment operations, but to a business’s long-term success. When customers receive accurate orders quickly, they’re more likely to be satisfied and become loyal shoppers.

Many warehouse operations can benefit from batch picking because:

-

It’s more efficient. Compared to other order picking strategies, like single order picking, batch picking is more efficient because workers can collect items for several orders at once, instead of revisiting the same storage location several times in a shift.

-

It enables faster picking rates. In addition to being able to pick several items at once, batch picking helps prevent sporadic picking. This generally translates to fewer pickers navigating warehouse aisles at any given moment, reducing bottlenecks and helping staff get to their next pick location quicker.

-

It reduces travel time. With defined picking routes that aim to maximize every step taken, pickers can avoid backtracking or repeating the same pick path several times in any given shift. This can greatly reduce travel time, improving picking efficiency.

-

It puts less stress on the workforce. Batch picking can reduce time spent traversing the warehouse, making the job less physically taxing for workers. And because pickers stay focused on one SKU at a time, it can be easier to focus on what’s in front of them, minimizing mental fatigue and increasing accuracy.

Batch Picking Examples

To better understand the batch picking process, it can be helpful to consider an example. Imagine three customer orders that need to be picked:

Customer A

- 40 packages of AAA batteries

- 20 units of copper wire LED lights

- 12 garden planters

Customer B

- 20 packages of AAA batteries

- 10 garden planters

- 5 hand trowels

Customer C

- 10 packages of AAA batteries

- 5 units of copper wire LED lights

Rather than pick each customer’s order individually before proceeding to the next, a warehouse worker using batch picking might first pick all 70 packages of AAA batteries for all customers and place them in a designated tote on a push cart. Next, the picker collects all 25 units of copper wire LED lights and places them in another tote on the same cart. Then the picker collects the five hand trowels for customer B and places them in another tote.

Before picking the garden planters for customers A and B — which are large and cannot fit on the pushcart — the picker brings all the batteries, LED lights and trowels to the sorting area. Finally, the picker uses a pallet jack to collect all 22 garden planters on one pallet and brings it to the sorting area to be sorted and packed for shipping with the other goods.

Batch Picking Case Study

Batch picking can significantly cut costs when implemented correctly. Take, for example, a fictional family pharmacy with a central warehouse that distributes items to its 50 retail stores in the Pacific Northwest.

After the company opened 15 new locations, its distribution center struggled to keep up with demand. Given the company’s fairly small scale, it opted to reassess its order picking strategies before incorporating robotics and other automated processes. After some analysis, warehouse managers recognized that single order picking was no longer sustainable, especially because each retail location generally ordered the same types of items, so it switched to batch picking. For each shift, managers used their WMS to establish optimal order batches and picking routes that enabled workers to pick several orders at once, instead of repeatedly taking similar trips throughout the warehouse.

Ultimately, the pharmacy was able to cut worker travel time by 55% and increase pick rate by 40%. And, despite the increase in demands, productivity gains enabled the company to reduce labor costs by 15%.

Batch Picking and Automation

While batch picking can improve accuracy and speed on its own, automated systems that use robotic or semi-robotic modules can enhance picking capabilities and further optimize the picking process. Here are a few types of warehouse automation systems that can be applied to batch picking:

-

Robots, such as collaborative robots (“cobots”) and autonomous mobile robots (AMRs), enhance the manual picking process by working collaboratively with employees. Cobots generally assist pickers by helping them navigate to the next picking location and providing other important picking information, like SKU quantities. Or, they might carry bins or totes for the picker. AMRs can autonomously navigate the warehouse and handle tasks like sorting or transporting inventory from point A to point B.

-

Automated storage and retrieval systems (AS/RS) can automatically collect items on demand. While there are a variety of AS/RS systems available, vertical lift modules (VLMs) are particularly useful for batch picking. These storage units essentially act like an industrial-scale vending machine; shelving trays are mounted inside a centrally located picking elevator. Directed by software, the user can input the items they need to access, and the VLM delivers the respective shelf to the operator at an access point.

-

Automated batch picking carts use software to optimize pick routes based on the cart’s real-time physical location. The cart itself has a computer and visual interface so pickers can reference their pick lists, and the cart typically can hold several discrete bins or totes. Automated batch picking carts can enhance efficiency by finding nearby single pick orders that can be easily picked during another assigned multi-ordered batch pick.

Optimize Batch Picking With Technology

As mentioned earlier, the benefits of batch picking can be further enhanced by using an OMS, WMS and inventory management tools. For example, an order management system can automatically manage an order’s life cycle, from the moment an order is placed to the time it’s delivered. The OMS can take that order data to automate order processing, thereby eliminating manual processes that can create bottlenecks and lead to human error, making it easier to fulfill orders quickly and accurately.

Meanwhile, a warehouse management system can automatically manage all resources within the distribution center. A WMS can help companies keep track of warehouse organization, bin locations and inventory. It can also help prevent overstock and stockouts and be linked to warehouse technologies like barcode scanners, so pickers can easily confirm when they’ve picked orders. What’s more, a WMS can use data to better manage warehouse tasks, like creating optimal pick strategies based on typical order types and warehouse layout.

Additionally, inventory management software can also improve order picking efficiency because it provides a real-time overview of inventory. This can be particularly useful in warehouses with fast-moving products that often need to be replenished. Any time spent waiting for SKUs to be replenished is time wasted and orders that take longer to ship. Inventory management tools can keep track of what products need to be restocked and when, so pickers never have to wait to fulfill orders.

By enabling order pickers to pick multiple items for multiple orders at the same time, batch picking is one way for warehouses and distribution centers to efficiently fulfill orders. Combined with automation and software like a WMS or OMS, the order picking process can be further optimized and help businesses get orders to customers with greater speed and accuracy.

Batch Picking FAQs

What are the costs and benefits of batch picking?

The cost of batch picking can vary based on picking system technology and complexity. Basic systems might use an order management system (OMS) to generate pick lists that appear on mobile picking devices. Others might take technology a step further to incorporate barcode scanners, pick-to-light systems or voice picking systems. The most elaborate — and generally most expensive — batch picking systems incorporate automation and robotics.

What is the zone picking method?

With zone picking, an order is split among multiple pickers who each pick different items within a single order. Each picker is assigned to a picking zone and only picks the SKUs within their zone. Zone picking lessens travel time and can prevent bottlenecks in aisles. Unlike batch picking, zone picking doesn’t require the same types of items to be ordered. However, it can be difficult to equitably distribute the workload because not all orders will require items from each zone.

What is picking in a warehouse?

Picking is the act of selecting products in preparation to be shipped. Employees called “pickers” locate, select and count the items needed to fulfill orders before delivering them to the packing and shipping area. There are several methodologies to streamline that process, including batch picking.

How do you calculate order picking accuracy?

Companies can calculate order picking accuracy by determining the number of orders that are picked in full and comparing them with orders that were short-picked, short-packed or mispicked. The formula is:

Order picking accuracy = (Number of accurate orders picked / Total number of orders picked) x 100