Any IT veteran will tell you that a successful ERP deployment doesn’t end with implementation. In fact, the initial launch is only the beginning of a company’s ERP journey. That’s because long-term ERP success also depends on how well the system is maintained over time. Regular ERP maintenance is key to keeping ERP systems updated with the latest innovations and running smoothly to support organizational growth. Using a combination of technologies and processes, ERP maintenance blends strategies for quick responses to unexpected issues, with proactive activities to prevent future problems. This article explores the various types of ERP maintenance that businesses should consider, the benefits they provide, best practices and how to avoid common maintenance challenges.

What Is ERP Maintenance?

When managing an ERP system, regular ERP maintenance is critical to ensure that the system not only remains fully operational but also aligns with evolving business needs, supports growth and mitigates risks associated with system failures or security breaches. Effective maintenance includes a combination of technical activities, strategic planning and support to maximize the value of an ERP system and maintain its longevity. Important ERP maintenance activities include identifying and fixing bugs, applying necessary updates and incorporating new features that enhance system performance and improve the user experience. A good maintenance program also ensures that the system adapts to changes in regulatory requirements and industry standards.

In addition, strategic ERP maintenance involves planning for future scalability and flexibility. As businesses grow and change, their ERP systems must be able to accommodate new processes, additional employees and, in many cases, more complex data requirements. Planning for a company’s future needs during maintenance activities allows the ERP system to remain a robust organizational backbone capable of supporting evolving demands.

Key Takeaways

- ERP maintenance involves a set of ongoing responsive and proactive processes that ensure the system operates smoothly, remains secure and continues to meet a company’s changing needs.

- ERP maintenance activities include regular system reviews, performance monitoring and applying patches and updates.

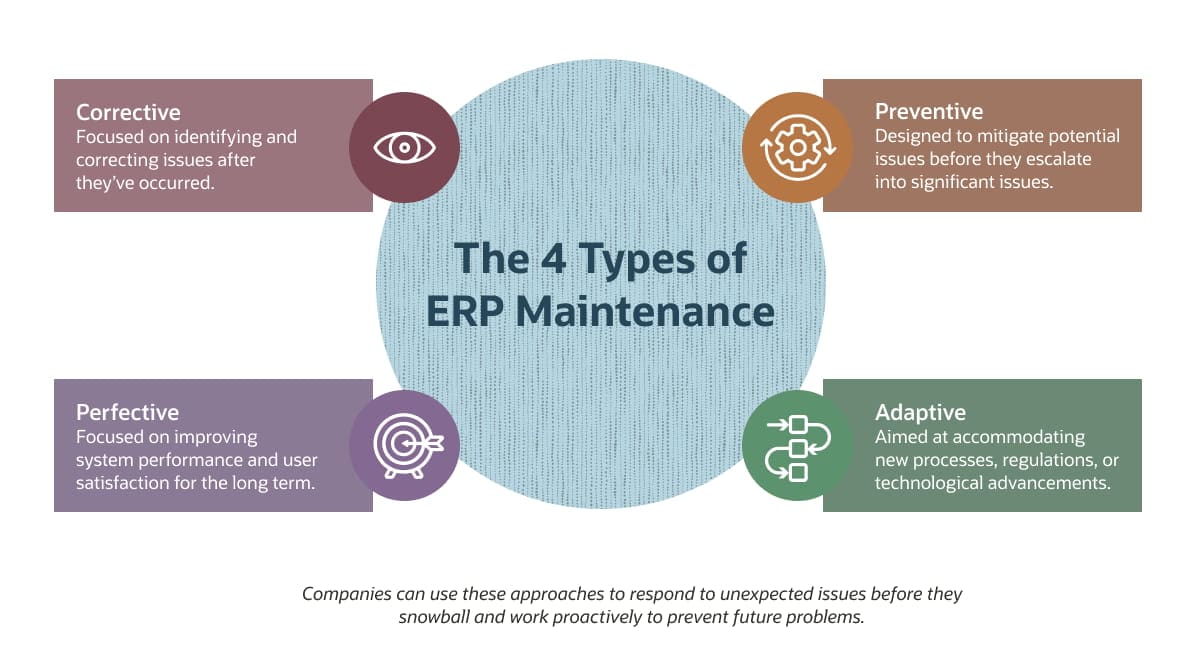

- The four main types of ERP maintenance are corrective, preventive, adaptive and perfective.

- Best practices for ERP maintenance include scheduling screenings, developing rigorous data protocols and regularly monitoring performance.

ERP Maintenance Explained

Worldwide, companies are forecasted to spend $183 billion on ERP software in 2024. The process of keeping an ERP system at peak functionality typically involves a combination of routine system reviews, performance monitoring and the application of patches and updates released by the software provider. In addition, proper maintenance includes developing data backup and recovery plans to safeguard against data loss. Businesses typically use four primary types of ERP maintenance: corrective, preventive, adaptive and perfective. The differences among these approaches (discussed in more detail below) primarily center on whether the maintenance is reactive to a current problem or proactive to prevent a future issue, plus whether it fixes a specific problem or improves overall system performance.

Regardless of the type of ERP maintenance involved, the process usually begins with a comprehensive evaluation of the system to pinpoint areas for improvement. The results of this evaluation dictate which type of maintenance effort is necessary, allowing a business to outline the specific changes required. After these changes are implemented, rigorous testing confirms their effectiveness while at the same time making sure the alterations don’t introduce new issues. Continuous monitoring post-implementation helps in evaluating the impact of the changes to make certain the ERP system delivers optimal performance and creates a smooth experience.

Cloud ERP Maintenance vs. On-Premises ERP Maintenance

ERP maintenance varies significantly between cloud-based and on-premises systems, primarily because of differences in infrastructure management, update processes and data security responsibilities. Many companies are moving toward cloud-based solutions. In fact, the cloud ERP market grew significantly in 2023, to nearly $50 billion and is expected to continue growing rapidly at an annual rate of nearly 16%, to $140 billion by 2030.

Because cloud-based ERP systems are hosted on the vendor’s servers, customers receive automatic updates and patches, without the need to tap into IT resources. Cloud implementations also assure businesses that systems are always running the latest version of the software.

With on-premises ERP systems, the company is responsible for manually implementing updates, managing hardware and ensuring data security, all requiring a dedicated IT team and potentially leading to longer downtimes during maintenance activities. As a result of these differences, ERP maintenance is generally simpler with cloud-based systems, letting companies focus IT resources on strategic tasks rather than tedious maintenance chores. In many cases, cloud-based maintenance also offers better scalability and improved cost-effectiveness.

The Importance of Regular ERP Maintenance

ERP maintenance provides businesses with clear benefits on several fronts. First and foremost, it safeguards investments in ERP technology by guaranteeing the reliability of the system, while also minimizing downtime and operational interruptions. It also gives companies an important competitive edge by allowing them to remain agile amid market changes. In addition, in an environment of constant cyber threats, regular maintenance helps companies maintain a consistent focus on security measures to safeguard critical business data. Finally, regular maintenance optimizes system efficiency, potentially lowering operational costs and increasing the return on ERP investments.

Types of ERP Maintenance

To keep ERP systems operating efficiently, companies have several different approaches at their disposal. The following processes ensure that companies are prepared to respond quickly to unexpected issues, such as system crashes, as well as lay the groundwork to prevent future snafus.

-

Corrective Maintenance

Corrective ERP maintenance is a reactive approach that focuses on identifying and correcting errors and other issues after they’ve occurred. Corrective maintenance is often initiated in response to specific identified problems that impact the reliability of the ERP system, such as system crashes, data integrity issues and malfunctioning modules that hinder financial reporting, inventory management or customer relationship management (CRM) capabilities.

By swiftly addressing and correcting system errors, businesses can minimize system downtime and prevent issues from escalating before they lead to more significant operational disruptions or data inaccuracies. Key components of corrective maintenance include error detection and diagnosis, often done by specialized IT teams using diagnostic tools and software logs to pinpoint the source of the problem and determine the most effective solution. Solutions often include applying patching software, adjusting configurations and updating system components to address issues.

-

Preventive Maintenance

Compared with corrective maintenance, preventive maintenance is a more proactive strategy designed to identify and mitigate the risk of potential issues before they occur to avoid significant problems down the road. The goal of preventive maintenance is to regularly review and update an ERP system to reduce the risk of unexpected system failures and operational disruptions that can lead to delays.

Keeping close tabs on the system to prevent errors allows a company to maintain business continuity while also helping to optimize system performance and extend the life span of the ERP system. For example, regular preventive maintenance helps companies avoid the pitfalls of outdated software, such as security vulnerabilities or incompatibilities with other business applications, thereby safeguarding against data breaches and enhancing overall system reliability.

The process of preventive maintenance includes conducting regular system audits, monitoring system performance and applying updates and patches in a timely manner. Several technologies can help. For example, automated monitoring tools alert administrators to potential issues before they become critical, and predictive analytics can forecast future system bottlenecks and vulnerabilities.

-

Adaptive Maintenance

Whereas corrective and preventive maintenance focus on responding to existing or potential ERP system problems, adaptive maintenance is focused on making necessary changes to accommodate new business processes, regulatory requirements or technological advancements. This ensures that the ERP system remains relevant and effective in supporting a company’s dynamic needs, as well as preventing obsolescence and supporting growth.

For example, changes in tax legislation often require changes to the financial modules of ERP systems. Using adaptive maintenance processes, the system is updated to comply with new legal standards so that companies can remain compliant while also minimizing disruptions to financial operations. Adaptive maintenance requires keen analysis of legislative, technological and business trends that might impact an ERP system. The process can be dramatically streamlined using cloud-based ERP systems, particularly those with modular architectures, because they allow for easier integration of new features and compliance with evolving standards.

-

Perfective Maintenance

Perfective maintenance of ERP systems improves the system’s performance and user satisfaction over the long term. For example, a company may implement perfective maintenance to streamline its inventory management processes within the ERP system, improving algorithms for better demand forecasting and inventory optimization. This not only boosts operational efficiency but also reduces costs associated with excess inventory and stockouts. Perfective maintenance relies on the analysis of employee feedback, system performance data and business process requirements to identify areas for enhancement. Business analytics and artificial intelligence (AI) tools can assist with perfective maintenance by providing insights into system usage patterns and identifying optimization opportunities.

11 Best Practices for ERP Maintenance

-

Schedule Regular Maintenance

Neglecting to schedule routine ERP maintenance can lead to several risks, including increased system downtime, vulnerability to security breaches and the gradual degradation of system performance. Unaddressed system bugs can escalate into critical issues, disrupting business operations and ultimately causing financial losses.

Scheduling regular ERP maintenance requires comprehensive planning and stakeholder involvement to succeed. Establishing a maintenance calendar that aligns with the business cycle can minimize the impact on a company’s day-to-day operations. Additionally, it’s crucial to prioritize maintenance activities based on their urgency. Automating routine maintenance tasks, such as data backup and system health checks, whenever possible can be a lifesaver, allowing staff to focus on higher-level upkeep tasks. Look for ERP systems with advanced automation features. Be sure to allot proper time for thorough maintenance activities and communicate maintenance schedules to all affected parties. Just as importantly, don’t overlook the need for testing after implementing updates and making other changes.

-

Conduct Training Sessions

For ERP maintenance to succeed, both IT professionals and non-IT staff must be proficient in using and managing the system effectively. Training sessions are vital for IT staff members responsible for the technical support of the ERP system, as well as for employees who interact with the system daily. On average, 26% of a company’s employees use its ERP system. If they aren’t properly trained on changes to an ERP system, they will make more errors and may fail to use the system properly, which can hinder efficiency.

Successful training for ERP maintenance should include a comprehensive curriculum that covers system functionalities, updates and best practices for system use and upkeep. Hands-on sessions will allow employees to experience real-life scenarios and troubleshooting exercises. Avoid one-size-fits-all ERP training. Instead, tailor instruction to the specific needs of different groups, keeping the content up to date with the latest ERP features and providing ongoing support and refresher courses to accommodate new hires as well as changes in the system.

-

Implement Data Protocols

Data protocols establish and enforce rules and procedures for data management within an ERP system. Implementing data protocols is a critical element of ERP maintenance because it ensures data integrity, security and consistency across the organization. Without these protocols, companies run the risk of experiencing data breaches and providing inaccurate reporting, which can lead to misinformed business decisions and operational inefficiencies. Implementing data protocols for ERP maintenance relies on establishing data entry standards, access controls, audit trails and regular data reviews.

Before implementing data protocols, companies should first conduct a thorough analysis of their data flows and identify potential vulnerabilities. Next, they should develop clear guidelines for data handling, train employees on these guidelines and use technology, such as encryption and multifactor authentication, to enforce data security measures. Regularly reviewing and updating these protocols are also crucial as business processes and technologies evolve. Be sure to provide training for employees on data handling procedures and establish clear enforcement mechanisms. In addition, regularly update data protocols to reflect changes in the business environment.

-

Monitor System Performance

Effectively monitoring system performance is essential for maintaining an ERP system’s health, ensuring that it continues to support business operations seamlessly and enabling proactive responses to potential issues before they affect organizational efficiency. Without regular monitoring, companies run the risk of regular system slowdowns, which can disrupt business operations and impact the bottom line.

Monitoring system performance involves tracking response times, load times and error rates, as well as assessing how efficiently the system is processing data and handling transactions. Performance monitoring tools can provide real-time analytics and automated alerts about potential performance issues. In addition, companies can set up thresholds for performance indicators to identify when the ERP system is underperforming. Regularly reviewing performance reports and trends can also help address potential issues preemptively before they escalate.

-

Update Security Measures

Diligently updating security measures is essential for safeguarding ERP systems against cyber threats and maintaining the ongoing security of business operations, which helps to solidify trust with customers. Neglecting to update an outdated firewall or unpatched software vulnerability, for example, could allow hackers to infiltrate the ERP system, resulting in the loss of sensitive customer information.

Companies should schedule regular vulnerability assessments, apply security patches quickly, update antivirus and malware protection and enhance access controls and encryption protocols. Technologies like security information and event management (SIEM) systems, intrusion detection systems (IDS) and regular penetration testing can spot and mitigate potential vulnerabilities. Remember that updates to ERP systems can sometimes impact third-party integrations, which may introduce security risks. To avoid issues, be sure to test integrations after an update.

-

Establish Feedback Channels

Feedback channels are essential for the iterative evolution of ERP systems because they build a culture of continuous improvement and engagement that supports the long-term success of the ERP initiative. Establishing feedback channels ensures that inefficiencies and potential system enhancements aren’t overlooked, so ERP users remain happy and productive. To establish feedback channels for ERP maintenance, companies can add surveys and feedback forms within an ERP system, plus regularly touch base through email and hold review meetings.

Companies should make these feedback channels easily accessible to all employees and actively encourage people to share both the positive aspects of the system and any hiccups they’re experiencing. Most importantly, companies must demonstrate that the input they receive actually spurs tangible changes. When companies are transparent about the fact that workers’ experiences lead to system improvements, people are motivated to continue to speak up.

-

Engage With ERP Vendors

Actively engaging with ERP vendors is an often overlooked but crucial best practice for maximizing the value and security of an ERP system. Regular communication with ERP vendors helps companies harness their expert knowledge and gain access to the latest updates, insights into upcoming features and ERP trends and support for addressing system challenges.

In addition, companies can participate in vendor-offered training and workshops to keep informed about best practices and updates. It’s also important to lean on vendor support for troubleshooting and optimization advice. Companies can designate team members to manage vendor relations, including scheduling regular review meetings with the vendor to discuss system performance and actively engaging in vendor-provided training programs to understand the full capabilities of the system.

-

Manage Customizations Carefully

Customizations are often necessary to tailor an ERP system to an organization’s specific needs and requirements, but at times customizations can introduce complexities, making the system harder to update and maintain. Failure to manage customizations can lead to increased maintenance costs, difficulties with applying patches from the vendor and potential system performance issues.

With careful management of customizations, the system remains stable and aligned with business needs. Companies should adopt a strategic approach by documenting all customizations, assessing the impact of those changes on system performance and upgrade paths and considering the long-term maintenance implications. Modular ERP systems can offer significant benefits when maintaining customizations because they allow for easier isolation and management of changes without impacting core system functionality. Prioritize customizations based on the business value they provide and invite IT and business stakeholders to participate in the decision-making process. Businesses should also regularly review customizations to assess their ongoing relevance and impact on system performance.

-

Create a Detailed Maintenance Plan

It should go without saying that businesses need to develop a detailed ERP maintenance roadmap to track the system’s optimal performance, security provisions and alignment with business goals. Without a clear maintenance plan, critical updates may be delayed or missed altogether, exposing the system to security risks or causing compatibility issues with other business applications.

The first step in building an effective ERP maintenance plan is assessing the current ERP system’s performance to identify areas for improvement and prioritize maintenance tasks based on their impact on business operations. Involving key stakeholders from both IT and business departments in the planning process will keep the roadmap aligned with broader organizational objectives. The plan should also detail maintenance schedules, the responsibilities of team members, procedures for applying patches and strategies for handling customizations and integrations. Companies will want to regularly review and update the plan to reflect changes in business needs or technology.

-

Be Proactive With Problem Management

Proactively managing problems is crucial to identifying and resolving ERP challenges quickly before they escalate into more significant issues and lead to increased downtime, higher maintenance costs and potential loss of data integrity, all of which can undermine business performance and reduce customer trust.

Taking a proactive approach to problem management includes regularly analyzing system logs, conducting performance audits and employing predictive analytics to identify patterns that may indicate future issues. Automated monitoring tools can also alert administrators to irregularities or potential problems in real time. Successful problem management also requires businesses to establish clear procedures for issue resolution, including prioritization guidelines, to ensure that the most critical issues are addressed promptly. It’s also vital to train staff to recognize the early warning signs of potential problems and understand the appropriate steps they need to take to manage issues before they get worse.

-

Allocate a Maintenance Budget

Companies must develop an ERP maintenance budget, guaranteeing that sufficient resources are available to keep the system running smoothly to support their business goals. Without allocating a proper budget to maintenance, companies run the risk of postponing necessary upgrades, resulting in system vulnerabilities and performance issues that could disrupt business operations.

To build an ERP maintenance budget, companies can start by assessing their previous maintenance costs. Next, forecast future needs based on how the business wants the system to evolve over time to meet business growth, and don’t forget to incorporate provisions for unexpected issues.

The maintenance budget should adequately cover regular updates, new security measures, training for IT staff and potential customization adjustments. Businesses can use financial planning tools and ERP analytics to accurately forecast maintenance costs and justify the investment to stakeholders by demonstrating the return on investment (ROI) of a well-maintained ERP system. Regular reviews and adjustments to the budget are also essential to respond to a company’s changing priorities. Remember to include a plan for future scalability in the budget as well.

Challenges in ERP Maintenance

Companies may experience a variety of challenges while maintaining their ERP systems, including everything from negotiating customizations to gaining user buy-in. Here’s how to overcome the most common challenges of ERP maintenance.

- Customizations and integrations: Companies often customize ERP systems to suit their specific needs, including integrating with third-party applications to create a unified system. However, businesses need to be aware that customizations and integrations can make ERP system updates more complex because they need to be compatible with modifications, potentially disrupting the seamless interaction between the ERP system and other platforms. This can lead to a variety of ERP failures, such as costly downtimes and degraded system performance. Companies can overcome these challenges by choosing ERP systems with natively integrated modules. Thorough testing before deployment and clear documentation of all customizations and integrations can also allow for seamless maintenance and upgrades.

- User resistance: ERP maintenance isn’t only a matter of updating technology; companies must also prepare their employees to adjust to changes in the system. If workers are unfamiliar with system updates, for example, they’re less likely to take full advantage of the system, which can negatively impact operational productivity and ROI. To overcome these challenges, companies should focus on conducting comprehensive training programs, communicating regularly about the benefits of updates and involving workers in the adjustment process to reduce resistance.

- Staff expertise: In many cases, ERP maintenance requires dedicated IT resources. If staff members lack in-depth knowledge of the system or tend to resist adopting new technologies, however, employees may use the system incorrectly, resolve problems more slowly and make costly errors. It’s important for businesses to invest in ongoing training and professional development for their IT teams, as well as foster a culture of continuous knowledge-sharing across departments to build a proficient and adaptable IT team. If companies choose cloud-based ERP solutions, ERP providers typically assume responsibility for maintenance as part of a monthly subscription fee.

NetSuite Makes ERP Maintenance Smooth and Efficient

NetSuite ERP offers a comprehensive, cloud-based solution that streamlines the maintenance process for businesses. NetSuite’s cloud infrastructure facilitates automatic updates, giving all customers access to the latest features and security enhancements without the need for manual intervention by IT staff and allowing employees to focus on strategic initiatives rather than routine system upkeep. NetSuite’s cloud-based approach also eliminates the need for on-premises hardware and its associated upkeep, which reduces the total cost of ownership and helps companies scale their ERP systems seamlessly as they grow. With its unified data model across finance, human resources, CRM and supply chain management, NetSuite ERP provides a single source of truth across the organization, reducing the complexities typically associated with data synchronization and system updates.

In addition, NetSuite’s SuiteCloud platform plays a crucial role in keeping the ERP maintenance process running smoothly, offering a suite of tools and services that enable customization and integration with other systems while allowing for seamless upgrades. This lets companies tailor their ERP systems to their unique needs while keeping them up to date on all necessary maintenance.

A combination of corrective, preventive, adaptive and perfective ERP maintenance empowers organizations to maximize their ERP investments. Companies that make a strong commitment to developing a detailed maintenance plan and staying ahead of potential problems can preserve the system’s functional integrity and also promote agility, positioning them to swiftly adapt to market dynamics and maintain a competitive advantage.

#1 Cloud ERP

Software

ERP Maintenance FAQs

How often should ERP maintenance be performed?

How frequently businesses must perform enterprise resource planning (ERP) system maintenance depends on several factors, including the complexity of the system, the number of transactions it processes and the rate of business change. Generally, routine maintenance tasks, such as data backups and system health checks, should be performed at least weekly, if not daily, while more comprehensive maintenance activities, such as applying patches or updates, should be planned quarterly or biannually. Companies should stay aligned with their ERP vendor’s update schedule to keep their systems as secure and efficient as possible.

What are the typical activities involved in ERP maintenance?

Typical enterprise resource planning (ERP) maintenance activities include applying software patches and updates to make sure the system remains secure and functions properly, performing routine data backups to prevent data loss, monitoring system performance and resolving any issues and carefully managing customizations and integrations so that they continue to meet business needs. Training workers on new features and other changes is also crucial for maximizing the system’s value.

Can ERP maintenance be managed in-house or is outsourcing a better option?

Enterprise resource planning (ERP) maintenance can be managed both in-house and through outsourcing, depending on a company’s size, expertise and resources. In-house management offers direct control over maintenance activities but requires a skilled IT team familiar with the ERP system. Outsourcing can be a better option for organizations lacking in-house expertise or looking to focus their internal resources on other core business functions, which can potentially reduce maintenance costs.

What is ERP in maintenance?

Companies can take advantage of enterprise resource planning (ERP) systems to manage and optimize companywide maintenance operations. Tasks include scheduling preventive maintenance, tracking repairs, managing inventory levels and analyzing maintenance data to improve decision-making and operational efficiency. A well-maintained ERP system helps make sure the equipment is reliable, downtime is minimized and asset management strategies are supported, all of which can streamline operations, reduce costs and boost productivity.

What is the job description of ERP maintenance?

Broadly speaking, enterprise resource planning (ERP) maintenance jobs should focus on the smooth operation and optimal performance of an ERP system. Responsibilities include performing regular system checks, applying updates and patches, troubleshooting issues and working with users and vendors to manage customizations and integrations. The role may also involve training people, documenting procedures and contributing to the system’s strategic development to meet business needs.

What does ERP stand for in management?

In management, enterprise resource planning (ERP) refers to a suite of integrated applications that an organization uses to collect, store, manage and interpret data from various business activities, including finance, manufacturing, human resources and customer relationship management. ERP systems aim to streamline and automate processes, providing a comprehensive real-time view of core business operations, speeding up processes and improving decision-making across the organization.

What is ERP as a service?

Enterprise resource planning (ERP) as a service refers to the delivery of ERP software over the internet as a cloud-based service, rather than through on-premises installations. Cloud-based implementations allow businesses to access the system on a subscription basis, eliminating the need for significant upfront investment in hardware and software. Cloud-based ERP systems also offer scalability and flexibility, allowing organizations to easily adjust resources based on current needs. Additionally, ERP services simplify maintenance and updates because the service provider manages these processes to keep the system secure and up to date.