Kitting is an inventory management technique that can help companies increase revenue, reduce costs and improve customer satisfaction. With kitting, companies define a set of complementary items that customers can order as a single unit. This often increases average order value and helps companies sell slow-moving items, while reducing warehouse picking and packing costs.

What Is Kitting in Warehouses?

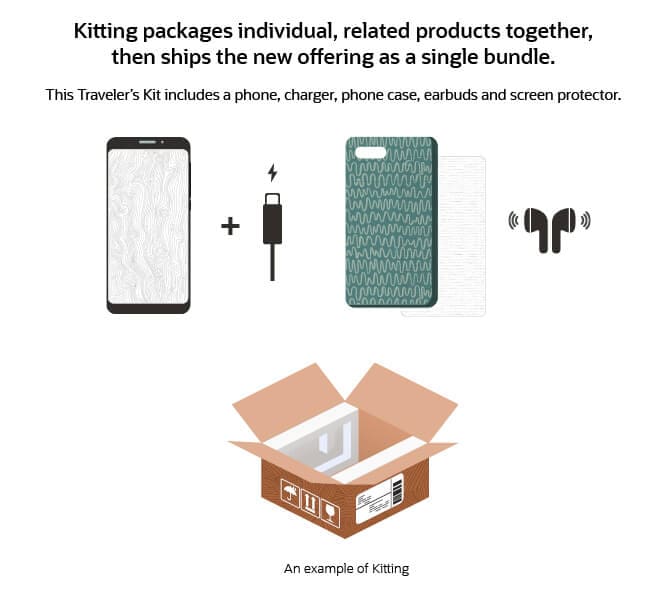

Kitting is a technique where different but related items are ordered, packaged and shipped together as a single "kit." For example, a seller of auto parts could create a kit containing everything customers need to overhaul the brakes on their cars. Often, warehouse workers preassemble the kits so, as soon as orders are received, the company can ship them immediately. This eliminates the need to individually pick, pack and ship each item.

Kitting vs. bundling:

The terms "kitting" and "bundling" are sometimes used interchangeably. Kitting and bundling both involve grouping multiple items together for sale and shipment. However, kitting specifically defines a set of complementary items that can be sold as a new product, while bundling is a broader term applied to any grouping of items. Examples of kitting include subscription boxes that include all the ingredients needed to make specific meals. Companies can also use kitting to improve the efficiency of their own operations, as when maintenance contractors provide their technicians with preassembled kits containing all the components they need for a specific job.

Key Takeaways

- Kitting is a technique where complementary items are ordered, packaged or shipped together as a single "kit" with a unique SKU.

- Kitting can help companies grow revenue and increase sales of slow-moving items.

- Kitting can also cut costs by trimming picking and packing time and reducing errors.

Inventory Kitting Defined

Inventory kitting is a method of organizing inventory into kits for sale or use. Each kit is assigned a unique stock keeping unit (SKU) number. Companies may physically organize and package the items in the kit in advance. Alternatively, they can use inventory management software to define a single SKU for a collection of items that are stored separately in the warehouse. With this approach, when the company receives an order, it picks the individual components and packages them together to fulfill the order. Inventory kitting gives more companies the flexibility to create a variety of kits that meet customer demand. Inventory kitting is popular with online stores and other retail businesses, but it's also a boon to many other industries, from pharmaceuticals to computer manufacturing.

Why Is Kitting Important?

Kitting can both increase revenue and reduce costs. It's a good method for highlighting items that pair well, resulting in higher-value orders for retailers, as well as better value for customers. Companies may also use kitting to move slow-moving products and dead stock: Hidden gems that don't sell well as individual items can be included in a kit that customers are more likely to buy, thus freeing up warehouse space for other merchandise. Preassembled kits also mean that fewer items need to be picked and packaged to fulfil customer orders. This helps businesses deliver products faster, while reducing manual labor and shipping costs.

Benefits of Kitting

Kitting offers many benefits, such as increased revenue, reduced costs and higher customer satisfaction.

-

Fewer errors.

Because all the items in the kit are defined in advance and often preassembled, there's less likelihood of the kinds of errors that can occur when picking and packing the items individually. In addition to raising customer satisfaction, more accurate order fulfillment can result in substantial savings, because the company ends up processing fewer returns.

-

More efficient use of warehouse space.

Combining products into kits can reduce the overall amount of packaging required, saving space in the warehouse.

-

Lower labor costs.

Employees spend less time fulfilling each order than if they had to pick each item individually. Productivity increases, and the labor-cost per order decreases.

-

Lower shipping costs.

Overall shipping costs are lower because it generally costs less to ship multiple items in a single package than to ship each item separately.

-

Higher sales revenue.

Kitting can help companies increase average order value and sell more products overall. At the same time, customers get better value, because buying the kit usually represents a savings over buying items individually.

-

Faster shipping.

Companies can turn around orders quickly because employees don't need to spend time locating, picking and packaging the individual items that compose the kit.

Manufacturing:

Kitting can speed up product assembly by ensuring that all the parts needed to build the product are available to workers when needed. It can therefore improve workflow and time management within the warehouse and on the assembly line.

Ecommerce:

An ecommerce company can boost average order value by including less-trendy, lower-priced items with more popular products. In that way, the company sells more products and the customer gets a better value. Kitting can also spur sales of languishing items. For example, a cosmetic brand has a hot-selling moisturizer. It just debuted a facial wipe containing that moisturizer, and also has some late-season eyeshadow colors it wants to move. By creating a kit comprising all those items, it can move older merchandise from its warehouse while creating awareness for its new product.

Private Kitting

Businesses can outsource the kitting process to private-label kitting services that gather products from different suppliers and package them together for sale. Some services can also provide branded marketing materials, packaging and product manuals. For example, a PC manufacturer might create a kit that includes a collection of products customers need, such as software, peripherals and cords. The manufacturer provides the list of items to a private-label kitting service, which, in turn, sources the items and ships them together under the manufacturer's brand name.

How to Manage Kitting

Kitting can be used by many different industries. Although the details vary, depending on the company, managing kitting generally includes a straightforward series of steps, from defining what each kit will contain to assembling and shipping it.

Kitting Process.

Key steps in the kitting process include:

-

Determine what the kit will comprise.

This decision is likely to be based on different factors. For example, some companies may consider grouping items customers often buy together; others may offer new products they want to highlight; and still others will focus on older products they need to sell.

-

Decide who will assemble the kit.

Companies may choose to assemble the kit themselves or outsource the process to a private kitting contractor that will ship and label the final offering.

-

Assign a new SKU.

Assigning a new product number to the kit allows the company to track sales and inventory.

-

Organize the items.

To increase picking efficiency, companies may preassemble the kits or locate the components of the kit near each other in the warehouse.

-

Ship the kits.

Collect and ship the items as a single package.

Kitting in Manufacturing

Kitting can help manufacturers simplify and accelerate product assembly while using warehouse space more efficiently. In manufacturing, kitting involves compiling a set of the raw materials and components required to make specific products. This ensures that the production team has everything it needs for the manufacturing process.

Manufacturers in almost any industry, from automotive to electronics to packaged foods, can use kitting. For example, consider a maker of nondairy ice cream that needs to expand production to keep up with fast-growing demand for several popular flavors. In its warehouse, the manufacturer stores the set of ingredients for each flavor together as a kit. When the company receives a large order, the kitted ingredients are automatically shipped to the manufacturing facility for production and distribution.

Implement Kitting With Inventory Management Software

Inventory management software can help companies streamline inventory operations, optimize warehouse space and fulfill orders quickly and accurately. Comprehensive inventory management solutions enable companies to group items into kits, define kit pricing and automatically update inventory for the individual items in the kit. Leading inventory management software also helps companies minimize inventory costs while keeping customers happy by tracking inventory in real time across multiple locations, automatically determining reorder points and managing safety stocks.

Conclusion

Kitting can help companies generate higher revenue and increase operating efficiency. At the same time, kitting can boost customer satisfaction by providing customers with a convenient collection of related items at an attractive price.

Kitting FAQs

What is kitting in a warehouse?

Kitting involves packaging related items together into a kit that is then sold as a single new product, with its own SKU.

What is a kitting process?

The kitting process starts by grouping together related items that can be packaged as a single product offering. Businesses then organize these items in the warehouse so they can be quickly packed and shipped to customers. Companies can also outsource kitting to specialized providers that source, assemble and ship the items.

What does kitting mean in logistics?

In logistics, kitting is the act of assembling multiple products into a single package or "kit," which is delivered to the customer.

What is the purpose of kitting?

Kitting can drive sales and increase efficiency. It helps businesses move less-popular inventory by pairing it with more trendy items. It also creates value for customers because the price per item is usually lower. Kitting, therefore, can help increase revenue and profit, as well as amplify customer satisfaction.